AEM Metal

- Refractory Metal Materials Manufacturer!TEL: +86-731-89578196 | EMAIL: [email protected]

Tungsten

Molybdenum

Tantalum

- Tantalum Powder

- Tantalum Carbide Powder

- Tantalum Oxide Powder

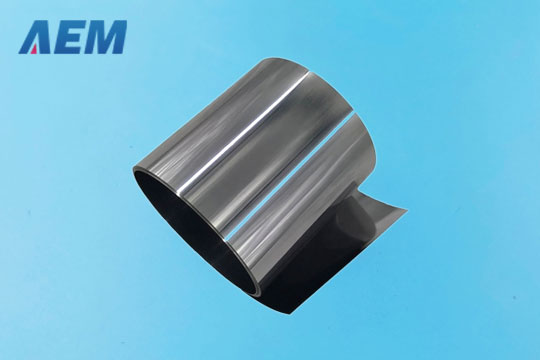

- Tantalum Foil

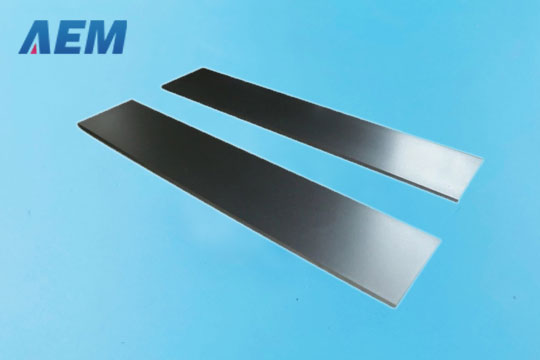

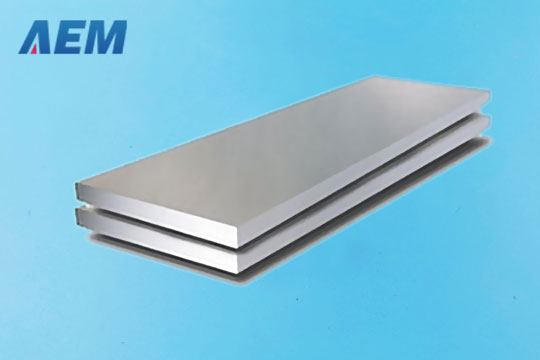

- Tantalum Sheet

- Tantalum Plate

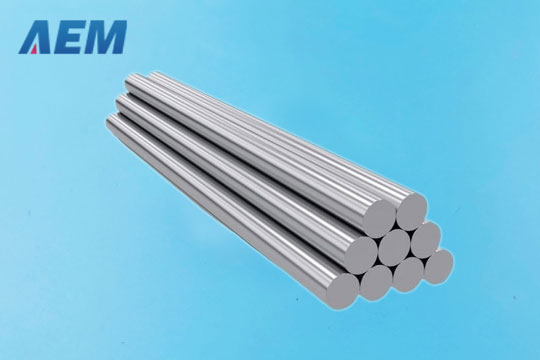

- Tantalum Rod

- Tantalum Bar

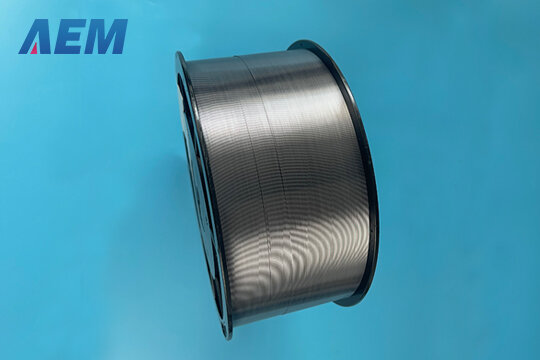

- Tantalum Wire

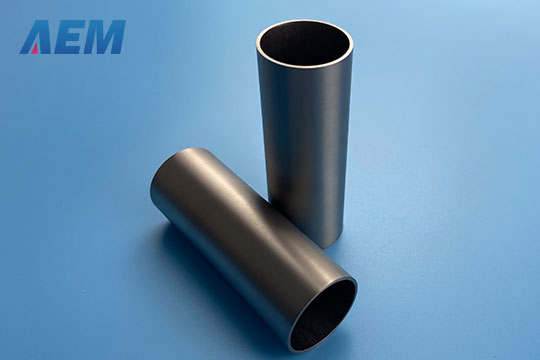

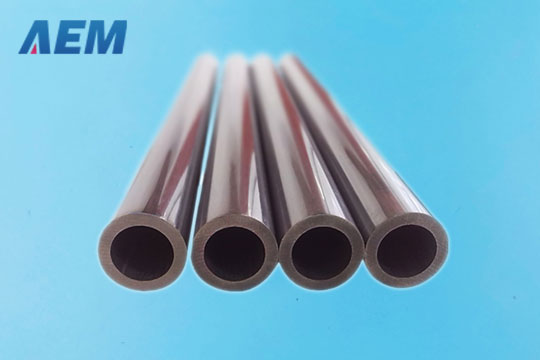

- Tantalum Tube

- Tantalum Crucible

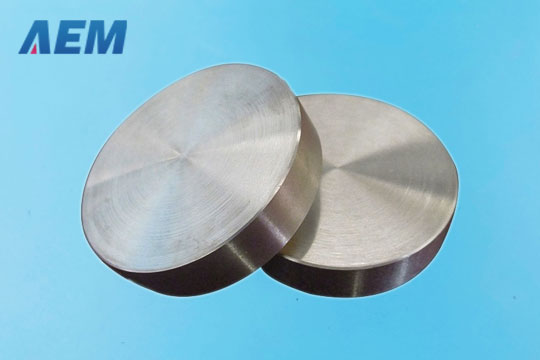

- Tantalum Sputtering Target

- Tantalum Tungsten Alloy

- Tantalum Niobium Alloy

- Tantalum Ingots

- Tantalum Nitride Powder

- Spherical Tantalum Powder

Titanium

- Titanium Foil

- Titanium Mesh

- Titanium Powder

- Titanium Wire

- Titanium Strip

- Titanium Sheet

- Titanium Plate

- Titanium Rod

- Titanium Bar

- Titanium Tube

- Titanium Sputtering Target

- Titanium Flange

- Titanium Fittings

- Titanium Fasteners

- Titanium Carbonitride Powder

- Titanium Carbide Powder

- Spherical Titanium Powder

- Custom Titanium Parts

- Titanium Sponge

- Nitinol Alloys

Zirconium

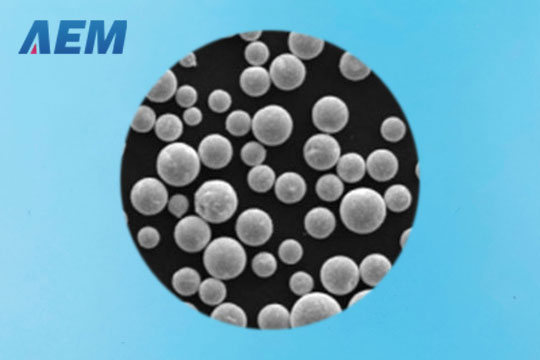

Spherical Powders

- Spherical Tantalum Powder

- Spherical Niobium Powder

- Hafnium Powder

- Zirconium Powder

- Spherical Cobalt Powder

- Spherical Chromium Powder

- Spherical Titanium Powder

- Spherical Tungsten Powder

- Spherical Molybdenum Powder

- Spherical Nickel Powder

- Copper Powder

- Spherical Iron Powder

- Spherical Aluminium Powder

- Spherical Silver Powder

- Rhenium Powder

- Other Powders