What is ASTM B387?

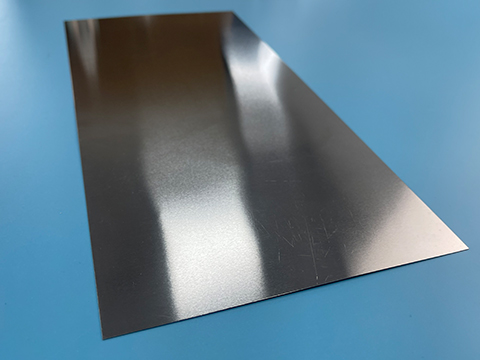

ASTM B387 is a technical standard created by ASTM International that sets the rules for making molybdenum and molybdenum alloy products. Specifically, it applies to items like plates, sheets, strips, and foils that are made through mechanical processes like rolling and forging—these are called wrought products.

The main goal of ASTM B387 is to make sure these products have consistent quality, especially for use in high-temperature and high-stress environments. This includes industries like:

-

Aerospace (e.g., jet engines and heat shields)

-

Semiconductors (e.g., thermal components)

-

Power generation (e.g., nuclear reactors)

-

Furnace construction (e.g., hot zone components)

The standard covers important material aspects, such as:

-

Chemical composition (how pure the molybdenum is)

-

Mechanical strength (like tensile strength and hardness)

-

Surface finish and dimensional tolerances

For engineers and buyers, ASTM B387 acts as a trustworthy guideline. When a product meets this standard, you know it's been tested and made to perform reliably—especially in extreme conditions.

At AEM Metal, we follow ASTM B387 closely to deliver molybdenum products that meet these strict requirements, giving customers worldwide the confidence they need in critical applications.

Scope and Coverage of ASTM B387

ASTM B387 applies to wrought molybdenum and molybdenum alloy products in four specific forms:

-

Plates

-

Sheets

-

Strips

-

Foils

These forms are produced through mechanical working processes such as hot rolling, cold rolling, or forging, rather than casting. This results in materials that have improved strength, better surface finish, and more precise dimensions—ideal for high-performance applications.

The standard is not limited to just pure molybdenum. It also includes several molybdenum alloys, each designed for enhanced performance in specific conditions. Common examples are:

-

TZM (Titanium-Zirconium-Molybdenum): For higher strength and better creep resistance

-

MoLa (Molybdenum-Lanthanum): For greater thermal stability

-

Mo-1 (Pure Molybdenum): For general-purpose use with good ductility

Each material covered by ASTM B387 is required to meet specific chemical and mechanical criteria, making the standard highly dependable for industries where failure is not an option.

This makes ASTM B387 an essential reference point for engineers and purchasing teams working in fields like:

-

Vacuum furnaces

-

Rocket propulsion systems

-

Medical imaging equipment

-

High-temperature tooling

At AEM Metal, we manufacture all these product forms with strict adherence to ASTM B387. This means our customers get uniform, high-quality materials that are ready for demanding applications worldwide.

Material Grades Defined by ASTM B387

ASTM B387 includes several grades of molybdenum and molybdenum alloys, each with specific characteristics suited for different environments and performance needs. Choosing the right grade is essential for ensuring your material performs well under expected conditions, such as high heat, mechanical load, or corrosive atmospheres.

Here are the most common grades covered by ASTM B387:

Mo-1 (Pure Molybdenum)

This is the standard grade for unalloyed molybdenum. It offers:

-

High melting point (over 2600°C)

-

Excellent thermal conductivity

-

Good strength at elevated temperatures

It’s often used in applications like furnace components, sputtering targets, and shielding where purity and thermal performance are critical.

TZM (Titanium-Zirconium-Molybdenum)

TZM Alloy is an alloyed grade made by adding small amounts of titanium and zirconium to molybdenum. TZM provides:

-

Higher tensile strength

-

Better creep resistance

-

Improved recrystallization temperature

It is ideal for high-stress, high-temperature environments such as aerospace parts, die-casting molds, and rocket nozzles.

MoLa (Molybdenum-Lanthanum)

Molybdenum lanthanum alloy also known as ML, this alloy contains lanthanum oxide. It enhances:

-

Resistance to grain growth

-

Dimensional stability at high heat

-

Life span in cyclic heating applications

MoLa is commonly used in x-ray equipment, lighting, and advanced furnace systems.

Each grade is tested for its chemical composition, mechanical strength, and ductility according to ASTM B387. This ensures that no matter which grade you choose, it will meet strict quality requirements for industrial performance.

At AEM Metal, we supply all major ASTM B387 grades, and we also help our clients select the most appropriate material based on their technical needs and working environment.

Key Mechanical and Chemical Properties

Molybdenum and its alloys are valued for their exceptional strength and thermal performance, especially in extreme environments. ASTM B387 defines minimum requirements for both mechanical properties and chemical composition, ensuring consistent quality across manufacturers.

Mechanical Properties

The mechanical performance of molybdenum products under ASTM B387 is tested in the as-rolled or stress-relieved condition, depending on the form. Key values include:

-

Tensile Strength: The maximum stress the material can withstand while being stretched. Molybdenum exhibits high tensile strength even at elevated temperatures.

-

Yield Strength: The stress at which the material begins to deform permanently. This is critical in load-bearing or structural applications.

-

Elongation: The amount the material can stretch before breaking. While molybdenum is not known for ductility, certain alloys like MoLa offer improved elongation.

Chemical Composition

ASTM B387 also defines maximum impurity levels to ensure high purity and performance. Trace elements such as carbon, oxygen, nitrogen, and silicon are tightly controlled.

For example, Mo-1 (pure molybdenum) typically contains:

-

Molybdenum (Mo): ≥99.95%

-

Oxygen: ≤ 150 ppm

-

Carbon: ≤ 30 ppm

-

Iron, Nickel, Silicon, etc.: ≤ 50 ppm each

Alloy grades like TZM and MoLa include small, intentional additions of titanium, zirconium, or lanthanum to enhance specific properties. These additions are also controlled within precise limits to maintain batch consistency.

The strength, purity, and stability of these materials make them reliable in environments where ordinary metals would fail due to oxidation, melting, or mechanical fatigue. ASTM B387 ensures that these performance factors are not just claims—they’re verified and documented.

At AEM Metal, all our molybdenum products are tested in-house and certified to meet or exceed ASTM B387 property requirements.

Testing, Certification, and Compliance

When working with advanced materials like molybdenum, reliability is everything. ASTM B387 doesn't just set performance standards—it also outlines how manufacturers must test, verify, and document that their products meet those standards.

This section ensures that every plate, sheet, strip, or foil delivered to the customer is fully traceable, compliant, and safe for critical applications.

Required Testing

ASTM B387 specifies that each product batch must undergo a series of mechanical and chemical tests before it can be certified. These include:

-

Tensile Testing: To verify strength and ductility at room temperature. Conducted in accordance with ASTM E8 or E8M standards.

-

Chemical Analysis: Confirms the purity of molybdenum and ensures alloying elements and impurities are within acceptable limits. Techniques like ICP-OES or combustion analysis are typically used.

-

Dimensional Inspection: Checks length, width, thickness, and flatness to ensure the product falls within the specified tolerances.

-

Visual and Surface Examination: Identifies surface defects such as cracks, inclusions, or laminations that could affect performance.

For special applications—such as aerospace, nuclear, or defense projects—additional testing like ultrasonic inspection or grain structure evaluation may also be performed.

Certification and Documentation

Each shipment must include a Mill Test Report (MTR) or Certificate of Conformance (COC), verifying that the materials:

-

Meet ASTM B387 mechanical and chemical requirements

-

Are produced from traceable heats or lots

-

Have been tested in an accredited or qualified laboratory

At AEM Metal, every order is accompanied by full documentation, including:

-

Material batch number

-

Test results

-

Manufacturing date

-

Compliance statement signed by a QA engineer

We also support third-party inspections by agencies such as SGS, BV, or customer-appointed auditors, especially for international and regulated projects.

Why This Matters

Accurate testing and complete certification are essential for:

-

Quality assurance and internal audits

-

Regulatory compliance (e.g., aerospace, nuclear)

-

Troubleshooting and traceability in case of operational issues

-

Customer confidence and procurement approval

Our clients trust us not only for the material but for the data and documentation that prove it will perform as promised. With ASTM B387 compliance, there is no guesswork—just verified reliability.

Why ASTM B387 Products from AEM Metal?

At AEM Metal, we don't just supply metal—we deliver certified performance.

-

Advanced Manufacturing: Precision rolling, forging, and annealing capabilities

-

Strict Quality Control: ISO-certified labs and ASTM-compliant protocols

-

Global Logistics: On-time shipping and custom export packaging

-

Custom Orders: Small batch production, custom dimensions, and rapid prototyping

From prototype runs to bulk shipments, we help clients around the world meet demanding project specs with confidence.

Conclusion

ASTM B387 is not just a technical standard—it's a gateway to performance assurance in your molybdenum applications. From extreme heat to mechanical stress, products made to this specification offer the reliability you need and the longevity you expect.

At AEM Metal, we combine materials expertise with global service. Whether you're sourcing for a niche research application or scaling up for mass production, our ASTM B387-certified molybdenum products are the answer.

Ready to request a quote or discuss your needs? Contact us today.