Titanium for Aerospace: The Ultimate Metal for Strength, Speed, and Reliability

views, Updated: June 13, 2025 by aemmetal

Why Titanium for Aerospace Is the Future

In the aerospace industry, choosing the right materials can make a big difference. From airplanes to spacecraft, every part must be strong, lightweight, and reliable. That’s why titanium has become one of the most important metals used today.

Titanium is a strong but lightweight metal. It’s as strong as steel but almost half the weight. That’s a big advantage in aerospace, where reducing weight helps aircraft fly farther, use less fuel, and carry more cargo or passengers. The less an aircraft weighs, the better it performs.

Another reason titanium is popular is its excellent resistance to corrosion. It doesn’t rust easily, even in harsh environments like salty air or space. This helps parts last longer and reduces the need for frequent repairs or replacements.

Titanium also stays strong in very high temperatures, which is important in parts like jet engines or rockets. Unlike some metals, it doesn’t weaken when things heat up.

Because of all these benefits, titanium is now used in many parts of aircraft and spacecraft, including:

-

Wings and body frames

-

Jet engine components

-

Landing gear

-

Satellite structures

-

Fasteners and connectors

At AEM Metal, we understand how important it is to use the best materials in aerospace projects. As a trusted titanium manufacturer and supplier in China, we provide high-quality titanium products that meet the strict standards of the aerospace industry. Our team works closely with customers to deliver reliable, cost-effective titanium solutions for everything from prototypes to large-scale production.

In short, titanium is the future of aerospace, and AEM Metal is here to help you build that future—stronger, lighter, and better than ever.

What Is Titanium?

Titanium is a silver-gray metal known for being very strong, yet surprisingly light. It was first discovered in the late 1700s, but it wasn’t used widely until the 20th century—especially when aerospace engineers realized just how useful it could be in aircraft and spacecraft design.

One of titanium’s best qualities is its high strength-to-weight ratio. This means it can handle a lot of force without being heavy. Compared to steel, titanium is just as strong—but weighs much less. And compared to aluminum, it’s a bit heavier but much stronger. That makes it a perfect balance between the two.

Titanium is also very resistant to rust and corrosion. It doesn’t easily react with water, air, or even salt, which is why it’s so popular in industries like aerospace, medical, marine, and chemical processing.

Another great feature of titanium is that it can withstand extreme temperatures. It stays stable and strong, even when it's very hot—such as inside a jet engine or during re-entry into Earth’s atmosphere. Many metals become weak or soft in those conditions, but titanium holds its shape and strength.

Here are a few key properties of titanium that make it ideal for aerospace:

|

Property

|

Why It Matters in Aerospace

|

|

Lightweight

|

Reduces fuel use, increases flight range

|

|

High strength

|

Supports structural loads safely

|

|

Corrosion resistance

|

Lasts longer, even in harsh conditions

|

|

Heat resistance

|

Performs well in engines and high-speed flight

|

|

Biocompatibility

|

Safe and non-toxic for various applications

|

Titanium is found naturally in the earth, often combined with other elements. But to use it in aerospace, it must go through special processes to remove impurities and improve its strength. These processes are carefully controlled to meet international standards like ASTM and AMS, which aerospace manufacturers trust.

There are different grades and types of titanium, each with its own benefits. Some are pure titanium, while others are titanium alloys—which means titanium mixed with other metals like aluminum or vanadium to make it even stronger or more heat-resistant.

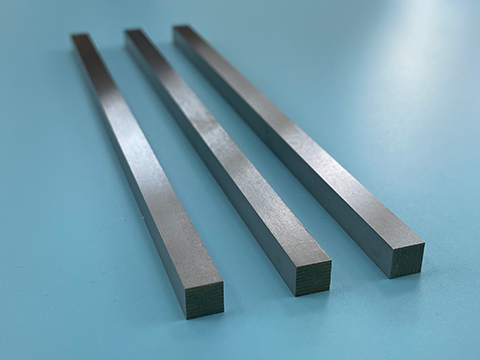

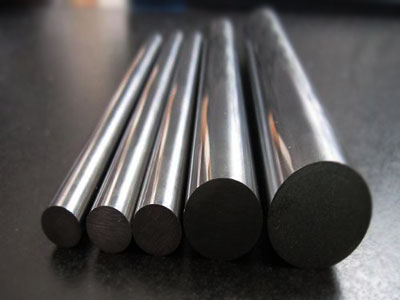

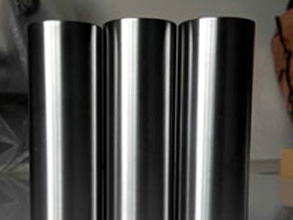

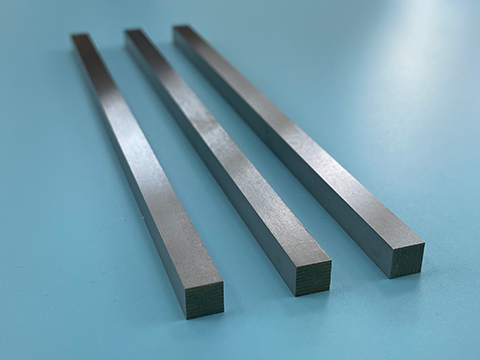

At AEM Metal, we specialize in producing and supplying titanium products that meet the strict demands of the aerospace industry. Whether you need titanium bars, sheets, plates, tubes, or custom components, we make sure the quality is right—from raw material to finished product.

Why Titanium Is Critical for Aerospace Applications

In the world of aerospace, choosing the right material isn’t just important—it’s mission critical. Aircraft and spacecraft must be strong, safe, and light enough to fly efficiently. That’s where titanium truly shines.

Let’s explore why titanium is such a smart choice for aerospace parts and structures.

Lightweight, Yet Incredibly Strong

Titanium is much lighter than steel, but just as strong. This means aerospace engineers can build strong parts without adding extra weight. Lighter aircraft need less fuel to fly, which helps airlines save money and reduce carbon emissions.

In spacecraft, weight savings are even more important. Every extra kilogram increases launch costs. So, using titanium helps engineers meet strict weight limits while keeping the structure safe and secure.

Excellent Corrosion Resistance

Aerospace vehicles often face tough environments—rain, humidity, salty ocean air, and even cosmic radiation in space. Metals like steel can rust, weaken, or wear out. But titanium holds up. It’s highly resistant to corrosion, meaning it stays strong and stable for a long time.

This durability leads to longer part life and lower maintenance costs, which is a big win for commercial airlines, defense projects, and space missions.

Aircraft engines and high-speed jets generate extremely high temperatures. Many metals start to weaken or deform under such heat. But titanium can handle the heat.

Some titanium alloys can resist temperatures of over 600°C (1,112°F) without losing their shape or strength. This makes titanium ideal for jet engines, exhaust systems, and other high-heat areas.

Reliable Under Pressure

At high altitudes or in outer space, parts face not just heat and cold but also intense pressure and vibration. Titanium has the toughness to stay strong under stress, making it safe for use in critical components like landing gear, structural frames, and engine housings.

Ideal for Both Manned and Unmanned Systems

Whether it’s a commercial airliner, a military drone, or a satellite, titanium is a reliable material. It works well in both manned and unmanned vehicles. That’s why major aerospace companies choose titanium for everything from fuselages to fasteners.

At AEM Metal, we understand how important performance and safety are in aerospace projects. That’s why we provide high-quality, certified titanium that meets industry standards such as ASTM, AMS, and ISO.

We offer titanium in bars, sheets, plates, tubes, and custom shapes—ready for use in engines, airframes, landing gear, and more. Our clients trust us for precision, consistency, and fast global delivery.

Quick Summary: Titanium's Aerospace Advantages

|

Benefit

|

Why It Matters

|

|

Lightweight

|

Reduces fuel use and improves efficiency

|

|

Strong under stress

|

Supports safety in structural parts

|

|

Corrosion-resistant

|

Withstands harsh air, water, and space environments

|

|

Heat-resistant

|

Performs well in engines and high-speed flight

|

|

Long-lasting

|

Cuts down on repair and replacement costs

|

Key Aerospace Applications of Titanium

Titanium is used in many critical parts of aircraft and spacecraft. From commercial airplanes to military jets and even satellites, this metal helps make machines safer, stronger, and more efficient.

Let’s take a closer look at how titanium is used across the aerospace industry.

Aircraft Structures

One of the biggest uses of titanium is in the structure of the aircraft—the frame that holds everything together. Parts like the fuselage, wing boxes, and bulkheads need to be strong but not heavy. Titanium offers the perfect balance.

It helps airplanes fly longer distances, use less fuel, and still meet strict safety and performance standards.

Jet Engines

Titanium is a top choice for jet engines because of its ability to handle extremely high temperatures and intense pressure. It’s commonly used in:

-

Compressor blades

-

Fan blades

-

Casings

-

Engine pylons

These parts spin at high speeds and heat up quickly. Titanium stays strong and stable, which is why engine makers trust it.

Landing Gear Components

The landing gear is one of the most important and heavily loaded parts of any aircraft. It has to support the full weight of the plane during takeoff, landing, and taxiing.

Titanium is strong enough to handle this stress. It also resists corrosion from runway chemicals and moisture, which makes it ideal for long-lasting landing gear systems.

Fasteners and Connectors

Even the smallest parts—like bolts, nuts, and screws—can be made from titanium. These fasteners hold together critical systems and must stay strong over time.

Using titanium fasteners means less weight and better performance, especially in parts exposed to vibration or harsh conditions.

Satellite and Spacecraft Structures

In space, there’s no room for error. Titanium is perfect for satellites, rockets, and space stations because it’s lightweight, durable, and can survive the extreme cold and heat of outer space.

Titanium is often used in:

-

Satellite frames

-

Fuel tanks

-

Rocket engine parts

-

Thermal shields

Because it doesn't rust and doesn’t weaken under radiation, titanium helps space vehicles last longer and work more reliably.

Military and Defense Aircraft

For fighter jets, drones, and military helicopters, strength, stealth, and speed are everything. Titanium helps military aircraft be more agile, tougher, and harder to detect on radar (especially when paired with special coatings).

It also improves survivability in combat by providing stronger protection with less added weight.

AEM Metal: Supporting All These Applications

At AEM Metal, we manufacture and supply the exact titanium products aerospace customers need. Whether it’s a precision-machined bar, a rolled sheet, or a custom-formed tube, we deliver products ready for use in:

-

Commercial aviation

-

Military defense

-

Space exploration

-

UAVs (Unmanned Aerial Vehicles)

With full material certifications, global delivery support, and strict quality checks, we help aerospace teams build with confidence.

Types of Titanium Alloys Used in Aerospace

Titanium used in aerospace isn’t always pure titanium. In fact, most parts are made from titanium alloys—which means titanium mixed with other metals like aluminum, vanadium, or molybdenum to improve strength, heat resistance, or flexibility.

Different types of titanium alloys are used for different aerospace applications. Choosing the right one depends on the part’s function, temperature exposure, and strength requirements.

Let’s look at the most common types used in the industry.

Ti-6Al-4V (Grade 5) – The Workhorse Alloy

Ti-6Al-4V is the most widely used titanium alloy in aerospace. It contains 6% aluminum and 4% vanadium, giving it a great balance of strength, corrosion resistance, and heat tolerance.

This alloy is used in:

-

Jet engine components

-

Airframe structures

-

Landing gear parts

-

Fasteners

It can handle high stress and heat—making it perfect for critical load-bearing parts.

Why it’s popular: Strong, lightweight, and reliable under pressure and heat. It’s often called the “workhorse” of aerospace titanium.

Ti-6Al-2Sn-4Zr-2Mo (Ti 6-2-4-2)

This alloy is designed for high-temperature strength. It’s typically used in jet engine components, where heat can exceed 500°C (932°F). It holds its shape and strength even under extreme thermal cycling.

Used in:

-

Turbine blades

-

Afterburner structures

-

Jet engine discs

Why choose it: Excellent performance under heat and pressure, making it ideal for engine environments.

Beta Titanium Alloys (e.g., Ti-10V-2Fe-3Al)

Beta alloys are more flexible and formable than other types. That makes them ideal for complex-shaped parts or areas where some bending is required during manufacturing.

Common uses:

-

Landing gear systems

-

Springs and structural supports

-

Fasteners needing cold-forming

Main benefit: High strength combined with good flexibility, which helps in parts that undergo bending or forming.

Alpha + Beta Alloys

These alloys combine the strength of beta titanium with the stability of alpha titanium. They’re used in structural areas where both strength and fatigue resistance are needed.

Applications:

-

Fuselage supports

-

Wing attachments

-

Internal engine housings

Why they matter: A great choice when durability and consistent performance over time are required.

Commercially Pure Titanium (CP Titanium)

Sometimes, pure titanium is the best option. It’s softer and easier to form, but still corrosion-resistant. It’s often used for parts that don’t face heavy loads but must resist chemicals, salt, or moisture.

Best for:

-

Hydraulic system tubing

-

Cooling systems

-

Air ducts

Why it’s used: Lower cost and easier shaping, with great corrosion resistance.

At AEM Metal, we help aerospace clients choose the best titanium alloy based on their specific needs. Whether you need strength, flexibility, or heat resistance, we supply certified materials with full traceability and consistent quality.

Our experienced team can recommend the right grade, shape (bar, plate, tube, or custom), and even suggest cost-effective alternatives without sacrificing performance.

Latest Trends in Titanium Aerospace Use

The aerospace industry is evolving rapidly—with new technologies pushing the boundaries of performance, sustainability, and efficiency. Titanium continues to play a central role in these innovations.

Let’s explore some of the most exciting trends where titanium is leading the way.

Additive Manufacturing (3D Printing) with Titanium

3D printing, also known as additive manufacturing, is transforming how parts are made. Titanium powders and wire are now being used to print complex aerospace components that are lightweight, strong, and material-efficient.

Key benefits include:

-

Faster prototyping and production

-

Lighter, optimized designs not possible with traditional machining

-

Less waste and better use of raw material

AEM Metal works with partners who use titanium for additive manufacturing, supplying high-purity powders and precision wire for these advanced processes.

Increased Use in Spacecraft and Satellites

As more private companies and government agencies enter space, the demand for lightweight and heat-resistant materials continues to rise. Titanium is now standard in:

-

Satellite structures

-

Fuel tanks

-

Thermal shielding

-

Propulsion systems

With its strength, corrosion resistance, and radiation durability, titanium ensures long-term performance in orbit and beyond.

Next-Generation Aircraft Designs

Titanium is vital in the development of:

-

Supersonic and hypersonic aircraft

-

Electric and hybrid propulsion systems

-

Autonomous drones and UAVs

-

Modular fuselage and wing structures

These platforms require materials that can handle extreme stress and temperature, while keeping aircraft lightweight and fuel-efficient.

Sustainability-Driven Material Selection

Airlines and aerospace manufacturers are under increasing pressure to reduce carbon footprints. Titanium is gaining popularity because it supports:

-

Fuel-efficient designs

-

Long service life

-

Recyclability and low maintenance

As the industry pushes toward net-zero emissions, titanium remains a top choice for building green aviation solutions.

Advanced Alloys and Material Science

New titanium alloys are being developed for even greater temperature resistance, formability, and fatigue life. These materials are expanding titanium’s role into deeper engine components, airframe joints, and novel composite-metal hybrid structures.

AEM Metal keeps pace with these changes by offering a wide range of standard and advanced titanium alloys, along with the technical support needed to apply them effectively.

Conclusion: The Future of Aerospace Runs on Titanium

Titanium has become an essential material in modern aerospace. Its unique combination of lightweight strength, corrosion resistance, and heat tolerance makes it ideal for everything from jet engines to spacecraft.

As the aerospace industry evolves—focusing on fuel efficiency, sustainability, and performance—titanium continues to lead the way.

At AEM Metal, we are proud to support aerospace manufacturers, engineers, and innovators with certified titanium products they can trust. From raw material to precision parts, our team delivers quality, reliability, and responsive service.

Whether you're building the next generation of aircraft or exploring new frontiers in space, AEM Metal is ready to be your titanium partner.

Contact us today to discuss your titanium requirements or request a custom quote.

Let’s build the future of aerospace—stronger, lighter, and smarter—with titanium from AEM Metal.