Ti6Al4V (UNS R56400) Titanium Alloy: Properties, Applications, and Souring Guide

views, Updated: November 14, 2025 by aemmetal

Introduction — Why Ti6Al4V (Grade 5 Titanium) Matters Today

Ti6Al4V, also known by its Unified Numbering System (UNS) designation

R56400, is the most widely used titanium alloy in the world. It is often referred to as

Grade 5 titanium and is known for its excellent balance of strength, weight, and corrosion resistance. These characteristics make it a top choice for demanding applications in aerospace, medical devices, industrial manufacturing, energy, and marine environments.

For engineers and purchasing managers, choosing Ti6Al4V means investing in performance and reliability. The alloy’s high strength-to-weight ratio allows for lighter components without compromising durability. Its corrosion resistance extends product life, especially in aggressive environments such as saltwater, chemical processing, or high-temperature operations.

At

AEM Metal, we specialize in supplying high-performance titanium and refractory metal products to clients worldwide. Whether you need

Ti6Al4V bars, plates, rods, or custom-machined parts, our team supports OEMs, fabricators, and research institutions with certified materials, strict quality control, and global shipping.

If you are looking for a dependable supplier of

Ti6Al4V / UNS R56400, this article will guide you through its key properties, common uses, product forms, and tips for selecting the right material for your application.

What Is Ti6Al4V? Understanding UNS R56400 & Grade 5

Ti6Al4V is a titanium alloy composed of approximately

90% titanium,

6% aluminum, and

4% vanadium by weight. This composition gives it a strong combination of light weight, high strength, and corrosion resistance. It’s classified as an

α+β alloy, meaning it contains both alpha and beta phase structures, which improves its mechanical performance across a wide temperature range.

The

UNS number R56400 is the standard designation for this alloy under the Unified Numbering System, used to ensure consistent material identification across global supply chains. In commercial and industrial settings, Ti6Al4V is also commonly called

Titanium Grade 5, especially under

ASTM and

AMS specifications.

Common Standards for Ti6Al4V / UNS R56400

Ti6Al4V is manufactured to meet a variety of international standards depending on its end-use:

·

ASTM B348 – For bars and billets

·

ASTM F136 / F1472 – For medical implants and surgical components

·

AMS 4911 / 4928 – For aerospace-grade sheet, plate, and forgings

These specifications help ensure that the alloy meets required levels of chemical purity, mechanical strength, and process traceability—especially important in critical industries like aerospace and healthcare.

Typical Product Forms

At AEM, we supply Ti6Al4V (UNS R56400) in a wide range of product forms:

·

Bar & Rod – For CNC machining, shafts, and precision components

·

Plate & Sheet – For aerospace panels, brackets, and structural parts

·

Wire & Tube – For medical implants, industrial use, and small precision parts

·

Custom Machined Parts – Based on customer drawings or OEM specifications

Whether you are looking for stock material or customized solutions, understanding the terminology—

Ti6Al4V,

UNS R56400, and

Grade 5—ensures you get exactly the right material for your project.

Key Properties of Ti6Al4V (UNS R56400)

Ti6Al4V (UNS R56400) is one of the most trusted materials in high-performance engineering because it offers an excellent balance of

mechanical strength,

light weight,

corrosion resistance, and

thermal stability. Below are the core properties that make it a go-to alloy across industries:

High Strength with Low Weight

Ti6Al4V provides

exceptional strength-to-weight ratio, far better than most stainless steels and aluminum alloys. This allows engineers to design components that are

lighter without sacrificing performance—especially important in aerospace and motorsports.

For example, a part made from Ti6Al4V can weigh 40–50% less than its steel counterpart while maintaining similar or better strength.

Excellent Corrosion Resistance

Thanks to its natural titanium oxide layer, Ti6Al4V resists corrosion in a wide range of environments—

air, seawater, saline solutions, and chemical processing conditions. This makes it suitable for long-term use in harsh environments like offshore platforms, medical implants, and marine equipment.

Fatigue and Creep Resistance

Ti6Al4V performs well under

repeated loading conditions, which is why it’s widely used in aircraft structures and rotating parts like shafts and fasteners. It also maintains mechanical stability under

moderate to high temperatures, which helps prevent deformation in demanding thermal environments.

Biocompatibility

Although the ELI version (Grade 23) is often preferred for implants, standard Ti6Al4V (UNS R56400) is still used in many

non-load-bearing medical applications and surgical tools due to its

non-toxic, non-reactive nature.

Thermal and Electrical Properties

·

Melting point: ~1,660°C (3,020°F)

·

Working temperature: Stable up to 400–500°C in most applications

·

Low thermal conductivity: Helps reduce heat transfer in high-performance environments

·

Non-magnetic: Useful for components where magnetic interference must be avoided

How Does Ti6Al4V Compare to Other Titanium Grades?

When choosing a titanium material for your project, it's important to know where

Ti6Al4V (UNS R56400 / Grade 5) stands in comparison to other available grades. While Grade 5 is the most commonly used titanium alloy, other grades may offer better formability, corrosion resistance, or biocompatibility depending on the application.

Here’s a breakdown of how Ti6Al4V compares to

commercially pure (CP) titanium Grades 1–4 and

other popular titanium alloys like Grades 7, 9, 12, and 23.

Situation 1: You Need Maximum Corrosion Resistance and Formability

Consider: CP Titanium Grades 1–4

These unalloyed titanium grades offer excellent corrosion resistance and weldability. They’re commonly used in chemical processing, desalination systems, and marine components.

|

Grade |

Strength |

Formability |

Corrosion Resistance |

Typical Use |

|

1 |

Very Low (~240 MPa) |

Excellent |

Excellent |

Heat exchangers, lab equipment |

|

2 |

Low (~350 MPa) |

Excellent |

Excellent |

Piping, tanks, marine hardware |

|

3 |

Medium (~450 MPa) |

Good |

Excellent |

Pressure vessels, structures |

|

4 |

Higher (~550 MPa) |

Moderate |

Excellent |

Aerospace, medical devices |

Compared to Ti6Al4V:

· Much easier to form and weld

· Lower strength (up to 60% less)

· Best for corrosion-critical but low-stress applications

Situation 2: You Need High Strength and Versatility

Best Choice:Ti6Al4V (Grade 5 / UNS R56400)

This is the go-to alloy when you need a

strong, lightweight, corrosion-resistant material that performs under stress and heat. It’s used everywhere from jet engines to orthopedic tools.

|

Property |

Value |

|

Tensile Strength |

~900 MPa |

|

Operating Temperature |

Up to 400–500°C |

|

Key Features |

Strength, fatigue resistance, corrosion resistance |

|

Common Applications |

Aerospace, medical tools, energy, motorsport |

Why it's so popular: it strikes the best balance for engineers who need

one alloy that does it all.

Situation 3: You Need Titanium for Medical Implants

Best Choice: Grade 23 (Ti6Al4V ELI)

Grade 23 is the medical-grade version of Ti6Al4V with

extra low interstitials (ELI). It offers better fracture toughness and superior biocompatibility, making it ideal for

load-bearing implants and sensitive medical applications.

| Compared to Grade 5 | Slightly lower strength, better ductility and toughness || Key Benefit | Safer for implants and cryogenic applications |

Situation 4: You Need Better Weldability or Cold Forming

Best Choice: Grade 9 (Ti-3Al-2.5V)

Grade 9 offers

moderate strength but is

much easier to form and weld than Ti6Al4V, especially in tubing applications. This makes it ideal for aerospace tubes, frames, and even bicycle components.

| Tensile Strength | ~620 MPa || Benefit | Easier fabrication with good strength |

Situation 5: You Need Exceptional Corrosion Resistance in Harsh Chemicals

Best Choices: Grade 7 and Grade 12

·

Grade 7: Similar to CP titanium but with

0.2% palladium, enhancing corrosion resistance in reducing acids like hydrochloric.

·

Grade 12: Alloyed with

Mo and Ni, offering resistance in hot acidic environments, often used in chemical plants and power stations.

|

Grade |

Key Alloying Element |

Strength |

Corrosion Specialty |

|

Grade 7 |

0.2% Palladium |

~350 MPa |

Excellent in reducing acids |

|

Grade 12 |

Mo, Ni |

~500 MPa |

Hot acid and chloride resistance |

Compared to Ti6Al4V:

· Lower strength

· Better for extreme chemical environments

· Ideal for industrial process equipment

Final Takeaway: Which Grade Fits Your Application?

|

Application Need |

Recommended Grade |

|

All-purpose strength & performance |

Grade 5 (Ti6Al4V) |

|

Load-bearing medical implants |

Grade 23 (Ti6Al4V ELI) |

|

Superior corrosion in acid |

Grade 7 or Grade 12 |

|

Lightweight, weldable tubing |

Grade 9 |

|

Basic corrosion + low stress |

CP Titanium (Grades 1–4) |

At

AEM, we primarily supply

Ti6Al4V / UNS R56400 in a wide range of forms—but we also support sourcing for other grades based on your engineering needs.

Typical Product Forms AEM Supplies in Ti6Al4V (UNS R56400)

At

AEM, we supply Ti6Al4V (UNS R56400) in a variety of product forms to meet the needs of different industries and manufacturing processes. Whether you're machining parts, building structural components, or producing high-precision devices, we can deliver the right material in the right format.

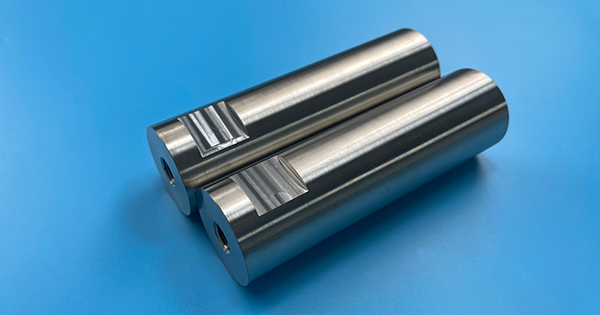

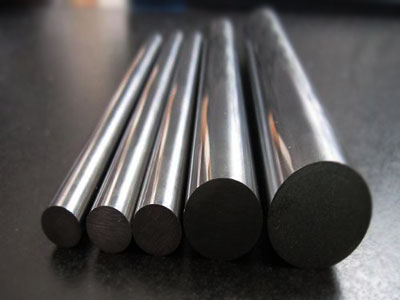

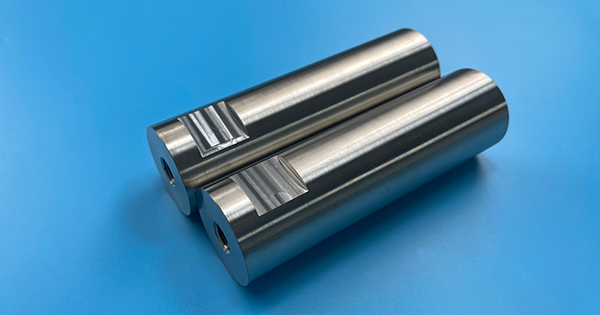

● Bars & Rods

Available in round, square, and rectangular shapes. Suitable for machining into aerospace parts, medical devices, fasteners, and industrial components.

● Plates & Sheets

Used for flat structural parts, brackets, panels, and cutting blanks. We offer thicknesses based on your requirements with good flatness and surface finish.

● Wire & Tubing

Thin wire for welding, 3D printing, or fine machining; tubing for aerospace, medical, and chemical applications. Precise dimensions and clean surfaces.

● Forgings & Blocks

Ideal for high-strength parts that require extra durability and grain refinement. Custom sizes available for heavy-duty industrial uses.

● Custom Machined Parts

We also support CNC machining based on your drawings—providing you with ready-to-use parts made from certified Ti6Al4V stock.

We ship globally with protective packaging and offer flexible order volumes—from small prototypes to full-scale production runs. Let us know your size, spec, and finish needs, and we’ll recommend the best product form for your application.

Key Applications of Ti6Al4V (UNS R56400)

Ti6Al4V (UNS R56400) is widely used across industries that require high strength, low weight, and corrosion resistance. Thanks to its versatility, it’s found in everything from aircraft components to surgical implants.

Here are some of the most common applications:

● Aerospace & Aviation

Ti6Al4V is a go-to material in aerospace due to its

high strength-to-weight ratio and ability to perform well at high temperatures.Typical uses include:

· Airframe structures

· Engine parts

· Landing gear components

· Fasteners and brackets

● Medical & Dental

Its

biocompatibility and mechanical reliability make Ti6Al4V ideal for medical tools and devices.Applications include:

· Surgical instruments

· Dental drills and tool handles

· Non-load-bearing implant components (load-bearing ones typically use Grade 23)

● Energy & Industrial Equipment

In oil, gas, and chemical processing, Ti6Al4V resists corrosion and handles stress well.Used in:

· Heat exchangers

· Pressure vessels

· Piping systems

· Subsea components

● Marine & Offshore

Thanks to excellent resistance to seawater corrosion, it’s used in:

· Propeller shafts

· Submarine hardware

· Deep-sea exploration tools

● Automotive & Motorsport

Lightweight and durable—ideal for high-performance applications:

· Suspension parts

· Engine valves

· Structural frames

● Additive Manufacturing (3D Printing)

Ti6Al4V is also popular in metal 3D printing (especially in powder form) for aerospace and medical components that require complex geometries.

Processing and Machining Ti6Al4V (UNS R56400)

Ti6Al4V is a strong and reliable titanium alloy, but it needs the right handling during production. Here's how it's usually processed and machined:

Forging and Shaping

Ti6Al4V is often hot-forged at high temperatures (around

900–950°C) to shape it into bars, plates, or blocks. This step helps make the material stronger and more uniform inside.

Heat Treatment

Some parts need extra strength or better fatigue performance. In those cases, Ti6Al4V is heat-treated using a process called

solution treatment and aging. This improves the alloy’s durability, especially in aerospace and high-load applications.

Machining Considerations

This alloy is tougher to machine than steel or aluminum. It generates more heat and wears down tools faster. To get good results, manufacturers use:

·

Slow cutting speeds

·

Plenty of coolant

·

Sharp, hard tools

At AEM, we also offer

machined parts made from Ti6Al4V if you want to save time and avoid handling it in-house.

Surface Finishing

After machining, the surface can be treated in different ways—like

polishing, pickling, or anodizing—to improve appearance, corrosion resistance, or fatigue strength, depending on the final use.

Conclusion: Sourcing the Right Ti6Al4V (Grade 5 Titanium) for Your Needs

Ti6Al4V, also known as

Grade 5 titanium, remains the most widely used titanium alloy across industries that demand high performance. Its strength, light weight, corrosion resistance, and versatility make it the preferred choice for aerospace components, medical tools, marine equipment, and industrial parts.

Whether you're developing precision parts or large-scale structures, choosing the right

Ti6Al4V supplier is key to ensuring material quality, consistency, and cost-effectiveness.

At AEM, we are more than just a material provider — we are a global

titanium metal manufacturer offering certified Grade 5 titanium bars, plates, rods, and custom-machined parts. Our team supports you with expert technical guidance, quality control, and flexible delivery options.

Ready to source Ti6Al4V for your next project? Get in touch with us today for a fast quote or technical consultation. We're here to support your production with reliable titanium solutions — from prototype to full-scale supply.