AMS 4911 Titanium Alloy: A Complete Guide to Properties, Applications, and Trusted Supply

views, Updated: June 27, 2025 by aemmetal

Introduction to AMS 4911

What is AMS 4911?

AMS 4911 is a titanium material standard used mainly in the aerospace, medical, and industrial fields. It's not a product itself but a set of rules and requirements that tell manufacturers how to make a specific type of titanium alloy — one that includes aluminum and vanadium. This alloy is often called Grade 5 titanium or Ti-6Al-4V, and it’s one of the most commonly used titanium types in the world.

The name AMS stands for Aerospace Material Specification. So when we say AMS 4911, we’re talking about a titanium alloy that meets the high standards set for use in airplanes, satellites, medical devices, and more.

Why does this matter? Because in these industries, materials must be strong, lightweight, and reliable. AMS 4911 makes sure the titanium used will do its job—whether it's holding up under stress in a jet engine or staying corrosion-free inside a medical implant.

In short, AMS 4911 is a trusted standard that helps engineers and manufacturers get the best quality titanium, every time.

Importance of AMS 4911 in Aerospace and Industrial Sectors

AMS 4911 is very popular in the aerospace industry. Airplane and spacecraft parts need to be strong but light. Titanium is perfect for this, and AMS 4911 ensures that the titanium used is tough enough to handle high speeds, heavy loads, and big temperature changes.

But it’s not just for flying machines. Industrial companies also use AMS 4911 titanium for equipment that works under pressure or in harsh environments, like deep-sea drilling machines, chemical tanks, or power plants. This alloy doesn’t rust easily, and it holds up well in extreme conditions.

One of the best things about AMS 4911 is that it comes with quality certificates and test results, so buyers know exactly what they're getting. There's no guessing or hoping—it’s all verified. That’s a big deal in industries where even a small flaw could cause a huge problem.

So whether you're building a jet, a heart implant, or a pressure valve, AMS 4911 gives you peace of mind and proven performance.

Composition and Properties of AMS 4911

Chemical Composition of AMS 4911 Titanium Alloy

AMS 4911 is made from a special type of titanium alloy known as Ti-6Al-4V, which simply means it contains 90% titanium, 6% aluminum, and 4% vanadium. Each of these elements plays an important role:

-

Titanium (Ti): The main ingredient. It gives the alloy strength, corrosion resistance, and a lightweight feel.

-

Aluminum (Al): Helps the alloy stay strong at high temperatures and improves its strength-to-weight ratio.

-

Vanadium (V): Boosts hardness and strength, especially when the material is under pressure.

These three elements are carefully balanced to create a material that’s tough, light, and resistant to corrosion. That’s why this alloy is used in things like aircraft, rockets, surgical tools, and industrial machinery.

AMS 4911 isn’t just known for its chemical makeup—it’s also famous for how it performs. Here are some of its key mechanical properties:

-

High Strength: It has excellent tensile strength, meaning it can handle a lot of pulling force without breaking.

-

Lightweight: Even though it's strong, AMS 4911 is much lighter than steel. This makes it perfect for designs that need to save weight, like airplanes or racing parts.

-

Durability: The material doesn’t wear out easily. It stands up well to repeated use and heavy stress.

-

Temperature Resistance: AMS 4911 performs well in both hot and cold environments, which is essential in aerospace and industrial settings.

These qualities make AMS 4911 a go-to material when reliability and performance matter most.

Corrosion Resistance and Thermal Behavior

Another big advantage of AMS 4911 is how well it handles tough environments. It has excellent resistance to corrosion, especially in salty, acidic, or humid conditions. That’s one reason it's used in marine and chemical applications.

It also handles heat very well. Even at high temperatures, it keeps its strength and doesn’t break down easily. That’s why it’s found in jet engines, where materials need to work perfectly under extreme heat and pressure.

In short, AMS 4911 offers a strong balance of strength, weight, and resistance—which is why engineers around the world trust it for their most demanding projects.

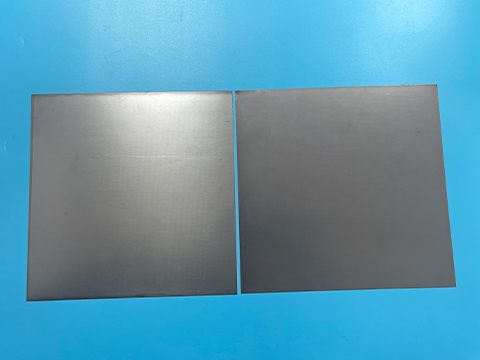

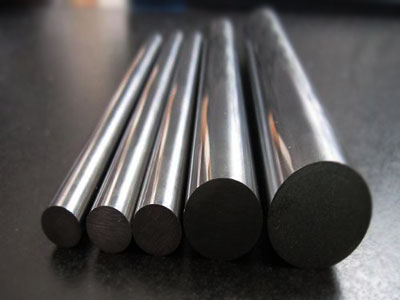

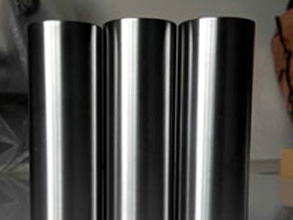

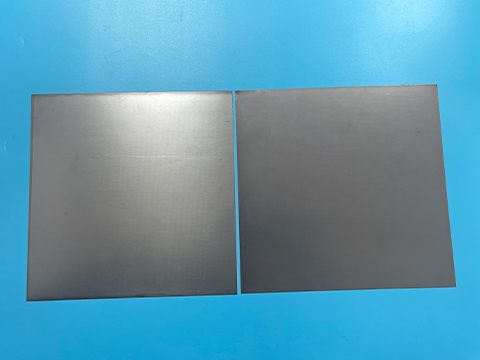

Available Product Forms: Plate, Sheet, and Coil

AMS 4911 titanium is available in several forms, which gives engineers and manufacturers flexibility depending on the project's needs. The most common forms include:

-

Titanium Plates: Thick and strong, used for structural parts that need to handle heavy loads.

-

Titanium Sheets: Thinner than plates, ideal for parts where saving weight is important, like aircraft skins or casings.

-

Titanium Coils and Strips: Thin, rolled titanium used in applications that require flexibility or continuous feeding into machines.

Each form is manufactured under strict quality control to ensure it meets the AMS 4911 standards for thickness, strength, and finish. Whether it’s a heavy-duty aerospace bracket or a delicate surgical instrument, there's a form of AMS 4911 that fits the job.

Heat Treatment and Fabrication Techniques

Before AMS 4911 titanium is ready for use, it often goes through heat treatment to improve its strength and durability. Common processes include:

-

Annealing: Softens the metal, making it easier to shape and improving ductility.

-

Stress Relieving: Reduces internal stresses that may form during machining or welding.

-

Solution Treating and Aging: Increases hardness and strength by changing the metal's internal structure.

Fabricating AMS 4911 requires skilled handling because titanium can be sensitive to heat and contamination. During shaping and forming, special tools and techniques are used to avoid cracks or defects. That’s why trusted suppliers like AEM Metal provide not just high-quality titanium, but also expert guidance on how to work with it.

Machinability and Weldability

Titanium alloys, including AMS 4911, are not the easiest to machine—but with the right tools and knowledge, it can be done effectively. Here’s what makes it a bit tricky:

-

Galling and tool wear: Titanium tends to stick to cutting tools, which can wear them out quickly.

-

Low thermal conductivity: Heat builds up during cutting, so coolant is essential.

Despite these challenges, AMS 4911 can be machined to very precise shapes with clean finishes. It just takes the right equipment and experience.

Welding AMS 4911 is also possible, especially using TIG (tungsten inert gas) welding, which gives clean, strong joints. However, it must be done carefully in an inert gas environment to prevent contamination, since titanium reacts easily with oxygen at high temperatures.

Professionals who understand these materials can machine and weld AMS 4911 into just about any shape needed for aerospace, medical, or industrial use—safely and reliably.

Industry Applications of AMS 4911

Aerospace Engineering and Aircraft Structures

One of the biggest users of AMS 4911 is the aerospace industry. In this field, every component must be strong, reliable, and as light as possible. AMS 4911 titanium fits the bill perfectly.

Aircraft parts made from this alloy include:

-

Fuselage panels

-

Wing sections

-

Hydraulic systems

-

Jet engine components

Why is it so popular in these areas? Because AMS 4911 combines high strength with low weight. That means aircraft can be lighter without sacrificing safety, which saves fuel and increases performance. Plus, it resists heat and corrosion, making it suitable for parts that face extreme conditions, like engine compartments or outer panels at high altitudes.

Biomedical Devices and Surgical Instruments

AMS 4911 isn’t just used in machines and engines—it’s also trusted inside the human body. The medical industry uses this titanium alloy for making:

-

Bone plates

-

Joint implants

-

Surgical tools

The reason is simple: AMS 4911 is biocompatible, meaning it doesn’t react with body tissues. It’s also non-toxic, lightweight, and extremely durable. Doctors and medical device companies choose this alloy when they need materials that last a long time and won’t cause irritation or corrosion inside the body.

Its clean finish and ease of sterilization make it ideal for surgical tools that need to stay sharp, clean, and safe.

Marine and Industrial Use Cases

AMS 4911 is also a great fit for tough industrial jobs and marine environments, where materials must stand up to saltwater, chemicals, and heavy use.

You’ll find this titanium alloy in:

-

Chemical processing equipment

-

Offshore drilling rigs

-

Heat exchangers

-

Industrial piping systems

In these industries, equipment often runs non-stop and faces rough conditions. AMS 4911 holds up well because it doesn’t rust, even in salty or acidic settings. Plus, it resists cracking and fatigue, making it a smart choice for equipment that must work safely over the long haul.

Because of its versatility and dependability, AMS 4911 has become a top choice in many sectors, proving its value far beyond the aerospace world.

Specifications and Standards

Certification and Compliance Requirements

AMS 4911 isn’t just about the material—it’s also about trust and traceability. Every product that claims to meet the AMS 4911 standard must follow strict certification guidelines. These include:

-

Chemical composition tests to ensure the alloy contains exactly the right amounts of titanium, aluminum, and vanadium.

-

Mechanical property tests, such as tensile strength, yield strength, and elongation.

-

Dimensional checks for thickness, flatness, and overall quality.

Suppliers must provide Material Test Reports (MTRs), showing that each batch meets all the required specifications. This paperwork is critical for buyers in aerospace, medical, or industrial fields where safety and performance are non-negotiable.

Manufacturers like AEM Metal understand the importance of certification and work to provide full documentation for every shipment, giving customers complete peace of mind.

Comparison with ASTM B265 and Other Titanium Grades

AMS 4911 is often compared with other specifications, especially ASTM B265, which also covers titanium sheets and plates. So what’s the difference?

-

AMS 4911 is more detailed, especially for aerospace use. It includes specific rules about heat treatment, surface condition, and performance.

-

ASTM B265 is a broader standard used in more general applications, like architecture or consumer products.

Both standards deal with Grade 5 titanium, but AMS 4911 is generally seen as more aerospace-focused and performance-oriented.

There are also other grades of titanium, like Grade 2 (pure titanium) or Grade 23 (a variation of Grade 5 with better biocompatibility). However, Grade 5 (AMS 4911) is by far the most widely used when strength, corrosion resistance, and temperature tolerance are needed all in one.

Traceability and Quality Assurance

One of the key benefits of buying AMS 4911-certified titanium is full traceability. This means:

-

You can trace each piece of metal back to the exact batch it came from.

-

You know how and where it was made.

-

You can verify every step of its testing and treatment process.

For engineers and manufacturers, this traceability builds trust and accountability. It ensures that the material will perform as expected under real-world conditions—especially in life-critical uses like aircraft components or medical implants.

By following the AMS 4911 standard, suppliers like AEM Metal help guarantee not just quality, but also safety, performance, and peace of mind.

Choosing and Sourcing AMS 4911

How to Select a Certified Supplier

When you're sourcing a high-performance material like AMS 4911, it’s important to go beyond price tags. The right supplier ensures not only material availability but also certified quality, reliable delivery, and technical support.

Here’s what to look for:

-

Full certification: Your supplier should provide AMS 4911-compliant Material Test Reports (MTRs) with every order.

-

Experience with titanium: Suppliers familiar with aerospace and medical standards will better understand your needs.

-

Customer support: Look for suppliers who offer guidance on material selection, fabrication, and application.

-

Consistent stock: A reliable inventory reduces downtime in manufacturing and development.

One such trusted supplier is AEM Metal. As a professional manufacturer and global supplier of titanium and other advanced metals, AEM Metal provides fully certified AMS 4911 titanium in plate, sheet, and coil form. Their reputation for on-time delivery, technical expertise, and material integrity has made them a preferred choice for many in the aerospace, medical, and industrial fields.

Factors Affecting Pricing and Availability

Several things can influence the cost and lead time for AMS 4911 titanium:

-

Raw material market prices: Titanium extraction and processing are energy-intensive, so prices can fluctuate based on supply and demand.

-

Processing level: Heat-treated or precision-rolled materials usually cost more than basic mill finishes.

-

Order size and customization: Smaller, custom-cut quantities may cost more per unit than large bulk orders.

-

Supplier location: Shipping and import/export regulations can also affect pricing and availability.

That’s why working with a responsive supplier like AEM Metal can help you plan better. They can provide realistic lead times and help optimize costs without compromising quality.

Handling, Storage, and Inventory Best Practices

Once you’ve sourced AMS 4911 titanium, you’ll want to make sure it’s stored and handled properly to maintain its high quality. Here are a few tips:

-

Store in dry, clean areas to prevent oxidation or contamination.

-

Avoid contact with reactive materials like chlorine or acids, which can damage titanium.

-

Use non-metallic tools when handling to avoid scratches or impurities.

-

Label inventory clearly for traceability and rotation.

AEM Metal can also offer storage advice and handling guidelines to help you get the most value from your materials.

In short, choosing the right supplier and managing your inventory well can make a big difference in the performance, cost, and lifespan of your AMS 4911 components.

Conclusion: The Strategic Role of AMS 4911 in Advanced Engineering

AMS 4911 is more than just a titanium alloy—it’s a critical material standard trusted across industries that demand strength, lightness, and long-term performance. From jet engines to surgical implants, this titanium grade has earned its reputation through reliability, precision, and unmatched resistance to harsh environments.

Its success lies in the details. AMS 4911 ensures that the titanium used meets strict chemical, mechanical, and quality standards. It’s a material that engineers choose not just because it’s strong, but because it’s certified, consistent, and trusted—all qualities that are vital when the cost of failure is high.

In aerospace, it allows for safer, lighter aircraft. In the medical world, it supports healing and longevity. And in harsh industrial environments, it stands up to pressure, corrosion, and time.

Of course, choosing the right material is only half the equation—you also need the right supplier. That’s why many engineers and buyers turn to AEM Metal, a globally trusted titanium manufacturer and supplier of AMS 4911 titanium. With a proven track record of quality, fast delivery, and expert support, AEM Metal ensures your titanium meets not only technical standards but also your performance expectations.

As industries evolve and innovation continues, AMS 4911 will remain a cornerstone material—one that engineers rely on for safety, sustainability, and success.