Introduction

Why AMS 4928 Ti-6Al-4V Is the Preferred Choice

AMS 4928 is a trusted standard for manufacturing Ti-6Al-4V, also known as Grade 5 titanium. This standard ensures the titanium meets strict guidelines, making it strong, lightweight, and corrosion-resistant.

Because of its strength and low weight, AMS 4928 titanium is ideal for aircraft parts, medical implants, and automotive racing components. Its resistance to corrosion also means it performs reliably in tough conditions, such as seawater or engine environments.

Manufacturers prefer AMS 4928 because it guarantees consistent quality. Every batch is carefully tested to ensure it meets exact chemical and mechanical standards, giving engineers confidence in their designs.

AEM Metal's Expertise in AMS 4928 Titanium

At AEM Metal, AMS 4928 titanium is our specialty. We thoroughly test each batch to meet the standard's precise requirements. Our facility carefully manages heat treatments to achieve optimal strength and durability.

We maintain complete records, providing transparency and traceability for every product. Whether you need custom bars, forged parts, or precision rings, AEM Metal supplies reliable AMS 4928 titanium tailored to your needs.

AMS 4928 Specification Overview

Scope, Purpose, and Key Updates

AMS 4928 is a detailed standard created by SAE International, specifically for the Grade 5 titanium alloy known as Ti-6Al-4V. Its main goal is to ensure titanium materials have consistent strength, quality, and reliability. Companies use this standard to produce titanium bars, wires, rings, forgings, and drawn shapes for demanding applications such as aerospace, medical, and automotive parts.

AMS 4928 clearly explains how to make and test titanium products. This includes rules for heat treatments, inspections, and mechanical testing. The specification is regularly updated to reflect new technologies or safety improvements, such as better methods for testing the strength and structure of the alloy. These updates make AMS 4928 a trusted guideline that engineers rely on to create high-performance components.

How AMS 4928 Differs from Similar Standards

AMS 4928 is similar to other standards, like AMS 4921, AMS 4965, and ASTM B348, but there are important differences.

AMS 4921 focuses on a stronger but less flexible type of Grade 5 titanium, usually for applications needing maximum strength.

AMS 4965 covers Grade 5 titanium specifically in an annealed state, making it easier to form or shape into complex parts.

ASTM B348 provides general guidelines for titanium bars and billets without detailed rules about heat treatment or strength.

AMS 4928, however, sets specific requirements for balanced strength and flexibility, ensuring predictable performance. It includes clear rules for heat treatments and testing, making it ideal for critical parts in aerospace, medical implants, and racing cars.

Understanding these differences helps companies choose the right titanium standard for their specific needs.

Mechanical Property Requirements

AMS 4928 sets strict mechanical property standards for Ti-6Al-4V (Grade 5) to ensure consistent performance in demanding environments. These properties define how the material behaves under stress, during stretching, and at elevated temperatures.

Typical Mechanical Properties of AMS 4928 Titanium

|

Property

|

Range / Value

|

|

Tensile Strength

|

130 – 135 ksi (896 – 931 MPa)

|

|

Yield Strength

|

119 – 125 ksi (820 – 862 MPa)

|

|

Elongation

|

8 – 10%

|

|

Reduction of Area

|

15 – 25%

|

|

Hardness

|

Approx. 34 HRC (varies by condition)

|

These values reflect the alloy's strength and ability to handle stress without breaking or deforming permanently. High tensile and yield strength make it suitable for structural parts under heavy loads, while elongation and reduction of area show it still offers flexibility and toughness.

AMS 4928 titanium is also reliable at elevated temperatures, performing well up to 400–500°C (750–930°F). This heat resistance is critical for aerospace and industrial uses where temperature changes are common. It allows components to maintain strength and shape without failure, even when exposed to extreme heat.

By specifying these properties, AMS 4928 ensures that Ti-6Al-4V materials meet the strict demands of aerospace, medical, and high-performance engineering applications.

AMS 4928 includes several types of titanium product forms, each made to meet specific needs in industries like aerospace, medical, marine, and motorsports. At AEM Metal, we supply all these forms with full certification and strict quality control to ensure they perform well in demanding conditions.

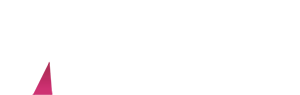

Bars and Wire

Bars are one of the most common titanium products covered by AMS 4928. They come in different shapes—mainly round but also square or rectangular—and a wide range of sizes. These bars are often used to make fasteners, bolts, structural parts, and shafts. Wire is much thinner and is usually used for welding, springs, and small components in aerospace or medical fields. Both bars and wire must meet strict standards for straightness, smooth surfaces, and consistent sizes.

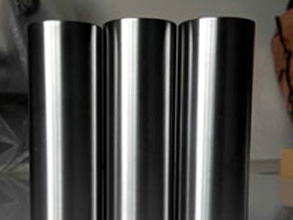

Forgings and Rings

Forgings and rings are made by pressing titanium into strong, solid shapes. This process makes the metal even stronger by aligning its internal grain structure. These forms are perfect for parts that must handle heavy loads, such as aircraft engine parts, wheels, or industrial equipment. Rings are often used in rotating parts like turbines. AMS 4928 requires careful testing of these shapes to ensure they are free of cracks and internal flaws.

Drawn Shapes

Drawn shapes are titanium products made by pulling the metal through a shaped die to create custom profiles. These are used when standard shapes won’t work for the design. For example, a thin, flat shape or a special groove may be needed for a specific part. AMS 4928 ensures these custom shapes still meet the same strength and quality standards as other forms.

Each product form under AMS 4928 is made to strict guidelines for strength, size, and quality. At AEM Metal, we provide these titanium products fully certified and ready to use, whether you need standard bars or custom-forged parts.

Typical Applications of AMS 4928 Titanium

AMS 4928 titanium (Ti-6Al-4V Grade 5) is one of the most widely used titanium alloys in the world—and for good reason. Its unmatched balance of strength, corrosion resistance, and light weight makes it a perfect fit for industries where performance and reliability are non-negotiable.

Aerospace and Aviation

In aerospace, every gram matters—and so does every ounce of strength. That’s why AMS 4928 titanium is used in critical components like aircraft fasteners, landing gear parts, engine mounts, and airframe structures. These parts face extreme forces, vibrations, and high temperatures, so the material must be light yet incredibly strong. Titanium’s resistance to fatigue and high-temperature oxidation makes it ideal for these demanding environments.

Medical and Surgical Devices

Titanium's biocompatibility and corrosion resistance make it a top choice in the medical industry. AMS 4928-certified Grade 5 titanium is commonly used for bone screws, joint replacements, surgical instruments, and spinal implants. These parts must remain stable inside the body for years without breaking down or reacting with tissue, and titanium does exactly that—safely and effectively.

Marine and Offshore Applications

In marine environments, where saltwater corrosion is a constant threat, AMS 4928 titanium stands out. It is used in offshore oil platforms, deep-sea valves, underwater shafts, and pumps, where it resists rust and maintains strength even after years of use. Its low maintenance and long service life make it a smart investment in harsh, wet conditions.

Speed, precision, and strength define motorsports. AMS 4928 titanium is used in suspension systems, drive shafts, valves, and fasteners for race cars and motorcycles. It helps reduce weight without compromising performance, giving engineers the edge they need in competitive environments.

Industrial and Power Generation Equipment

For industries like chemical processing and power generation, AMS 4928 titanium is a reliable option for heat exchangers, pressure vessels, and rotating parts. Its ability to handle heat, pressure, and aggressive chemicals ensures long-term performance and reduced downtime.

From the skies to the sea floor—and everywhere in between—AMS 4928 titanium delivers performance that professionals trust. At AEM Metal, we supply this material with full certification, making it ready for use in these demanding applications right out of the box.

AEM Metal's AMS 4928 Offering

At AEM Metal, we specialize in supplying high-quality AMS 4928 titanium products tailored for performance-driven industries. With years of experience in titanium processing and certification, we understand exactly what our customers need—reliable material, fast turnaround, and full compliance with industry standards.

Full Range of AMS 4928 Products

We offer a complete selection of Grade 5 titanium forms certified to AMS 4928 specifications. This includes:

-

Titanium Bars – Available in a variety of diameters and lengths for machining or structural use.

-

Titanium Wire – Supplied in coils or straight lengths for welding, medical, and aerospace applications.

-

Forgings – Open-die and closed-die forgings for parts requiring superior grain flow and strength.

-

Rings – Seamless titanium rings precision-forged for high-performance rotating parts.

-

Drawn Shapes – Custom profiles manufactured to meet complex design needs.

All products undergo complete inspection and are delivered with full certification, including test reports and traceability documents.

Value-Added Services

To save our clients time and reduce processing steps, AEM Metal also provides value-added services, such as:

-

Cut-to-size bars for faster production setup

-

Rough and precision machining for tight tolerance requirements

-

Heat treatment options to meet specific mechanical properties

-

Ultrasonic testing and surface finishing, all done in-house

These services are handled by our skilled technicians using advanced equipment, ensuring that each order meets both the technical specs and delivery schedule.

Reliable Supply, Trusted Support

We understand that industries like aerospace, defense, and medical cannot afford delays or uncertainty. That’s why our inventory, production, and quality control systems are designed to deliver AMS 4928 titanium on time, every time.

When you partner with AEM Metal, you're not just buying titanium—you’re gaining a reliable supplier who understands your industry, meets your technical requirements, and delivers value through every stage of the process.

Conclusion

AMS 4928 titanium, also known as Ti-6Al-4V Grade 5, is one of the most trusted materials for parts that need to be strong, lightweight, and long-lasting. It’s used in everything from airplanes and medical tools to racing cars and marine equipment—because it works reliably, even in tough environments.

What makes AMS 4928 special is the strict standard behind it. This standard makes sure every piece of titanium meets exact rules for strength, flexibility, surface quality, and heat treatment. So when you use AMS 4928 titanium, you know what you're getting—consistent quality you can trust.

At AEM Metal, we supply fully certified AMS 4928 titanium in the form of bars, wire, rings, forgings, and more. We carefully test every batch, track it from start to finish, and offer services like cutting and machining to make your job easier.

Contact AEM Metal today to speak with our technical team or request a custom quote tailored to your project needs. We're here to help you get the right material, right on time.