When your project is weight-sensitive, material choice is never just a “spec sheet decision.” It affects part performance, manufacturing yield, delivery time, and the total cost you carry from prototype to volume production. That is exactly why **magnesium vs titanium** is a common comparison for engineering teams and industrial buyers.

At a high level, magnesium is known for being extremely lightweight and cost-effective for certain structures and housings. Titanium is known for high strength, excellent corrosion resistance, and long-term reliability in demanding environments. But the best material is not universal. It depends on what your component must survive: impact loads, cyclic fatigue, salt spray, heat, chemical exposure, or strict safety requirements.

This guide breaks down the differences in a practical way. You will see how magnesium and titanium compare in weight, strength, corrosion behavior, manufacturability, and purchasing factors like lead time and supply stability. The goal is simple: help you match the material to your real working conditions, so your team can avoid over-engineering, reduce risk, and purchase with confidence.

Basic Overview of Magnesium and Titanium

Magnesium and titanium are both used when weight matters, but they are not interchangeable materials. They behave differently in real production—especially in strength, corrosion resistance, and processing difficulty. A clear understanding of each metal upfront makes the later comparison much easier to apply to your own part.

What Is Magnesium?

Magnesium is widely known as the lightest structural metal used in industry. Its main advantage is simple: it helps reduce part weight quickly, often without major redesign.

In most real applications, magnesium is used as an alloy rather than a pure metal. Alloying improves strength and stability, and it also helps with manufacturability. Magnesium alloys are commonly produced through casting and then finished by machining, which is why magnesium is frequently used for housings, frames, and lightweight components where extreme strength is not the top requirement.

From a buyer’s perspective, magnesium is often attractive for:

- lightweight designs that are cost-sensitive,

- parts that can be cast efficiently,

- projects that prioritize fast production cycles.

At the same time, magnesium typically needs proper surface protection and smart design choices if the part will face moisture, salt, or harsh service conditions.

What Is Titanium?

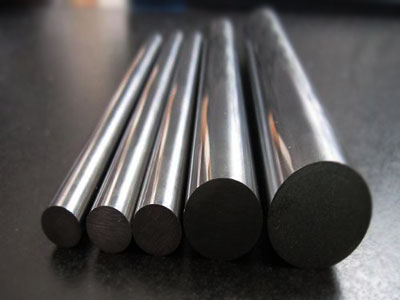

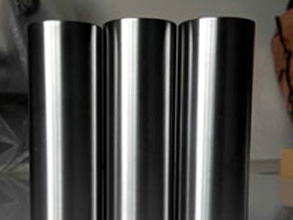

Titanium is chosen when a part must stay strong and stable in demanding environments. While titanium is heavier than magnesium, it delivers much higher strength and better long-term reliability, which is why it is common in aerospace, medical, marine, and chemical equipment.

Titanium is supplied as commercially pure grades and as titanium alloys. Pure grades are used when corrosion resistance and formability are the priority. Alloys are used when higher strength, fatigue performance, or elevated-temperature capability is required.

For purchasing teams, titanium usually means a higher unit cost and stricter processing requirements. Machining and joining often take more control, time, and tooling. However, if your component needs strong safety margins, corrosion resistance, and long service life, titanium can be the more economical choice over the full lifecycle of the part.

Magnesium vs Titanium — Core Material Properties

When evaluating "magnesium vs titanium", qualitative descriptions are not enough for engineering or purchasing decisions. What matters is measurable data: density, strength range, corrosion behavior, and thermal limits. A side-by-side comparison makes these differences clearer and easier to apply to real projects.

Key Material Properties Comparison Table

|

Property

|

Magnesium (Typical Alloys)

|

Titanium (CP & Alloys)

|

|

Density

|

~1.74 g/cm³

|

~4.5 g/cm³

|

|

Tensile Strength

|

150–330 MPa

|

240–1,100+ MPa

|

|

Yield Strength

|

90–250 MPa

|

170–950 MPa

|

|

Elastic Modulus

|

~45 GPa

|

~105–120 GPa

|

|

Fatigue Performance

|

Moderate

|

High

|

|

Corrosion Resistance

|

Low–Moderate, coatings often required

|

Excellent, natural oxide layer

|

|

Max Continuous Service Temp.

|

~120–200 °C

|

~400–600 °C

|

|

Thermal Conductivity

|

~70–160 W/m·K

|

~15–25 W/m·K

|

|

Electrical Conductivity

|

Relatively good

|

Poor

|

|

Typical Processing

|

Casting, machining

|

Forging, machining, additive

|

|

Relative Material Cost

|

Lower

|

Higher

|

Weight and Density

Magnesium is about 60% lighter than titanium. If your design target is maximum weight reduction and loads are limited, magnesium offers a clear advantage. Titanium is heavier, but still far lighter than steel, and often enables thinner sections due to its higher strength.

Strength and Load Capacity

Titanium’s strength range is significantly higher, especially when alloys are used. This allows titanium components to handle higher stresses, cyclic loads, and safety-critical applications. Magnesium alloys can meet moderate strength needs but usually require thicker designs to compensate.

Stiffness and Dimensional Stability

Titanium is more than twice as stiff as magnesium. This matters for parts where deflection, vibration, or dimensional accuracy is critical. Magnesium parts may flex more under the same load, which must be considered during design.

Corrosion and Environmental Exposure

Titanium forms a stable oxide layer that protects it in aggressive environments, including saltwater and chemical exposure. Magnesium lacks this natural protection and typically requires coatings or surface treatments. From a risk-management perspective, titanium is more forgiving.

Thermal Performance

Magnesium conducts heat much better than titanium, which is why it is often used in housings or frames that also serve as heat dissipation paths. Titanium maintains strength at higher temperatures but does not spread heat efficiently.

Manufacturing and Processing Differences

When choosing between magnesium and titanium, manufacturing is often the deciding factor. It affects not only part cost, but also lead time, quality consistency, and production risk. Understanding how each metal is typically processed helps you avoid surprises after design approval.

Machining and Fabrication

Magnesium is generally easy to machine. It cuts smoothly, tools last longer, and parts can be produced quickly. This makes magnesium suitable for components with complex shapes, internal cavities, or high production volumes. For many buyers, this translates into lower machining cost and shorter delivery time.

Titanium is more difficult to machine. It holds heat at the cutting edge and puts more stress on tools, so machining must be done more slowly and carefully. This increases processing time and cost, especially for complex or tight-tolerance parts. Working with an experienced titanium supplier is important to keep quality and lead time under control.

Casting, Forming, and 3D Printing

Magnesium is well suited to casting. Complex parts can be formed close to final shape, reducing the amount of machining needed afterward. This is a key reason magnesium is widely used for housings and structural parts produced in large quantities.

Titanium is rarely used in standard casting for industrial parts. Instead, it is usually supplied as forged or rolled material and then machined to final shape. This process is slower but provides strong and reliable mechanical performance. Titanium is also commonly used in metal 3D printing for specialized applications, where design flexibility is more important than unit cost.

Joining and Surface Protection

Magnesium parts often need careful design when it comes to joining and corrosion protection. Welding is possible in some cases, but many designs rely on screws, inserts, or bonding. Protective coatings are commonly applied to improve corrosion resistance, especially in humid or outdoor environments.

Titanium can be welded successfully, but the process must be well controlled. Once processed, titanium naturally resists corrosion, so it usually needs less surface protection than magnesium. This can simplify long-term maintenance in harsh environments.

What This Means for Buyers

Magnesium is often the better choice when you need fast production, lower cost, and complex shapes in high volumes. Titanium is better suited for parts that must remain strong and reliable under stress, corrosion, or long-term use—even though manufacturing is more demanding and expensive.

Application Comparison by Industry

Aerospace and Aviation

In aerospace, titanium is the safer and more common choice. It is strong, resists corrosion, and performs well under vibration and repeated stress. That is why it is used for structural parts and components where reliability is non-negotiable.

Magnesium is used more carefully. It can reduce weight in housings or non-critical structures, but it usually needs strong corrosion protection and conservative design. If the part will see humidity, salt exposure, or long maintenance intervals, titanium typically carries less risk.

Automotive and Transportation

In automotive production, magnesium is often selected for practical weight reduction at scale. It works well for cast parts such as housings, brackets, and structural frames, where complex shapes and high-volume output matter. When surface protection is planned correctly, magnesium can offer a strong balance of weight, cost, and production efficiency.

Titanium is used less in mainstream vehicles because it is expensive to process. It shows up more in motorsports, premium platforms, and performance-critical components. Buyers usually choose titanium when they need high strength, long fatigue life, or better corrosion resistance in a smaller, lighter part.

Medical and Biomedical Applications

Titanium is widely used in medical devices and implants because it is highly biocompatible and corrosion resistant inside the human body. It is also supported by mature standards and documentation, which helps medical buyers control compliance and traceability.

Magnesium is mostly used in specialized research or niche medical applications, especially where controlled biodegradation is being explored. For most standard purchasing needs in medical manufacturing, titanium remains the proven and commonly accepted option.

Electronics and Consumer Devices

Magnesium is popular for device housings and frames because it is light and can be cast into thin, complex shapes. It also transfers heat better than titanium, which is useful for electronics that need thermal management. This is why magnesium alloys are common in portable equipment where weight and heat dissipation both matter.

Titanium is used when strength, rigidity, and premium durability are the priorities. It is often chosen for higher-end product frames or components where long-term wear resistance and structural feel matter more than manufacturing cost. In many consumer devices, titanium is selected as a premium performance material rather than a cost-driven material.

Conclusion: Making a Confident Magnesium vs Titanium Decision

Choosing between magnesium and titanium is easier when you focus on three basics: where the part will be used, how much load it must carry, and how long it needs to last. Magnesium is often the better fit when your goal is lower weight at a lower cost, especially for housings and structural parts with moderate loads. It performs well when corrosion protection is planned from the start.

Titanium is usually the safer option when the part must stay strong and stable over time. If your application involves high stress, repeated loading, saltwater, chemicals, or long service life targets, titanium reduces risk and delivers more predictable performance.

If you are considering titanium for your next build, reach out to AEM Metal—one of the titanium metal manufacturers in China—to confirm the right grade, form, and inspection documents before you place the order.