Titanium Forging Explained: From Process to Applications and Custom Parts

views, Updated: December 26, 2025 by aemmetal

Introduction – Why Titanium Forging Matters

Titanium is widely used in industries that demand materials with high strength, low weight, and excellent corrosion resistance. But how titanium is processed plays a major role in how well it performs.

Forging is one of the most effective ways to shape titanium into parts that are strong, reliable, and built for demanding environments. Unlike casting or machining, the forging process compresses and aligns the metal’s internal grain structure—resulting in improved mechanical properties across the entire part.

This makes forged titanium the material of choice for critical applications like:

-

Aircraft landing gear and turbine components

-

Medical implants and surgical tools

-

Marine hardware, valves, and pressure fittings

In this guide, you’ll learn how titanium forging works, the benefits it offers, what grades are commonly used, and what to consider when sourcing custom forged titanium parts.

What Is Titanium Forging?

Titanium forging is a manufacturing process that uses heat and pressure to shape solid titanium into high-strength parts. Unlike casting, which involves pouring molten metal into a mold, forging keeps the titanium solid but heated — and forms it by pressing it into shape.

The titanium is typically heated to 800°C–950°C, depending on the grade. At this temperature, the metal becomes soft enough to form, but not melted. Using large presses or hammers, the billet is compressed into the required shape — whether that's a ring, block, disc, or custom form.

What makes forging different is how it improves the internal structure of the metal. The pressure forces the grain flow to follow the shape of the part. This greatly increases strength, fatigue resistance, and reliability — especially in parts that must handle high loads or repeated stress.

Because titanium reacts with oxygen at high temperatures, forging is usually done in controlled environments to protect the surface and preserve material quality.

In short, forged titanium parts are stronger, tougher, and more dependable than those made by casting or machining alone — which is why they’re widely used in aerospace, medical, and other critical industries.

How the Titanium Forging Process Works

Titanium forging involves several key steps, each designed to shape the material while preserving its strength and structural integrity. Here's how the process typically works:

1. Material Selection & Preparation

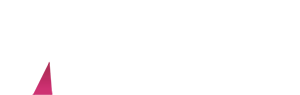

The process begins with selecting the right titanium grade based on the part’s application — for example, Grade 5 (Ti-6Al-4V) for aerospace, or Grade 23 for medical implants. Billets or bars are then cut to size, cleaned, and prepared for heating.

2. Heating

Titanium billets are heated to a precise temperature range — usually between 800°C and 950°C. This makes the metal soft enough to forge while maintaining its solid form. Proper temperature control is critical to avoid grain damage or oxidation.

3. Forging / Deformation

Using high-tonnage hydraulic presses or mechanical hammers, the heated titanium is forged into shape.

-

Open-die forging is used for larger or simple shapes like blocks and rings

-

Closed-die forging is used for near-net-shape components with tighter tolerances

The forging force aligns the metal’s grain structure with the shape of the part — improving strength, fatigue resistance, and overall performance.

4. Cooling and Heat Treatment

After forging, parts are cooled under controlled conditions. Additional heat treatment may be applied to adjust hardness, relieve internal stress, or enhance specific mechanical properties.

5. Final Machining & Surface Finishing

Forged parts are then machined to final dimensions, followed by surface treatments such as polishing, pickling, or coating — depending on the application. Parts may also undergo ultrasonic testing, hardness checks, or grain flow inspections to ensure quality.

Typical Applications:

-

Aircraft structural components

-

Turbine engine parts

-

Pressure vessels

-

High-stress industrial parts

Why it’s forged:

Forging maximizes the strength and fatigue performance of Grade 5 by refining the grain flow to follow the shape of the part — critical for flight-critical and load-bearing applications.

Common Titanium Grades for Forging

Titanium comes in multiple grades, each with its own balance of strength, corrosion resistance, formability, and cost. In forging, the right grade selection depends on the demands of the application — from structural aerospace components to medical implants or chemical-resistant parts. Below are the most commonly forged grades and why they’re chosen:

Grade 2 – Commercially Pure Titanium

Overview:

Grade 2 titanium is unalloyed titanium with high corrosion resistance and good ductility. It's easy to forge and weld, making it a popular choice in industries that require strong performance in harsh environments but don't need the highest strength levels.

Key Properties:

-

Moderate strength (~350 MPa yield strength)

-

Excellent resistance to seawater and oxidizing chemicals

-

Good workability and weldability

-

Low density (4.5 g/cm³)

Typical Applications:

-

Heat exchangers

-

Marine hardware

-

Medical device housings

-

Chemical tanks and fittings

Why it's forged:

Its softness allows for easy shaping and forming. When corrosion resistance is more important than strength, Grade 2 offers an ideal balance of performance and cost-efficiency.

Grade 5 (Ti-6Al-4V) – Aerospace Industry Standard

Overview:

Titanium Grade 5 is the most widely used titanium alloy in the world, accounting for over 50% of titanium usage. It's a two-phase alpha-beta alloy that offers excellent mechanical properties and corrosion resistance. Forging enhances its already strong fatigue resistance — especially important in aerospace and high-performance industries.

Key Properties:

-

High strength (~880–950 MPa yield strength)

-

Excellent fatigue and creep resistance

-

Strong corrosion resistance

-

Good temperature stability (up to 400°C)

Typical Applications:

-

Aircraft structural components

-

Turbine engine parts

-

Pressure vessels

-

High-stress industrial parts

Why it’s forged:

Forging maximizes the strength and fatigue performance of Grade 5 by refining the grain flow to follow the shape of the part — critical for flight-critical and load-bearing applications.

Grade 23 (Ti-6Al-4V ELI) – Medical & Implant Grade

Overview:

Grade 23 titanium is a purer version of Grade 5, with tighter controls on oxygen, nitrogen, and iron content. These lower interstitials improve ductility, toughness, and biocompatibility — making it ideal for medical and surgical use.

Key Properties:

-

High strength (~830 MPa yield strength)

-

Excellent toughness and fracture resistance

-

Biocompatible and corrosion-resistant

-

Approved for long-term implantation

Typical Applications:

-

Hip and knee implants

-

Bone screws and plates

-

Dental implants

-

Surgical tools

Why it's forged:

Forging ensures a dense, defect-free structure with better fatigue resistance — essential for long-term medical implants exposed to repeated stress in the human body.

Other Titanium Grades for Specialized Applications

-

Grade 7: Similar to Grade 2 but with added palladium for superior corrosion resistance in acidic or chloride-rich environments. Used in electrochemical and desalination systems.

-

Grade 9 (Ti-3Al-2.5V): Lower strength than Grade 5 but better formability. Often used in tubing for aerospace and sporting goods.

-

Grade 12: Offers higher strength than Grade 2 and superior corrosion resistance, especially in mildly reducing acids. Common in chemical processing and heat exchangers.

Selecting the Right Grade:

The choice of titanium grade affects not only performance but also forgeability, machining needs, and cost. At AEM Metal, we support full-grade selection, technical consultation, and material certification to help U match the right titanium alloy to your application.

Advantages of Forged Titanium Parts

Forging titanium doesn’t just shape the material — it transforms its internal structure to deliver higher performance, reliability, and durability. Compared to casting or machining from stock, forged titanium parts offer clear technical and operational advantages, especially in critical industries like aerospace, medical, marine, and energy.

1. Improved Strength and Fatigue Resistance

During forging, the grain flow of the titanium is compressed and aligned to follow the contours of the part. This grain alignment significantly boosts tensile strength, impact resistance, and especially fatigue life — which is essential for components that undergo repeated stress, such as turbine discs, landing gear, or bone implants.

2. Superior Structural Integrity

Forged titanium parts have a denser, more uniform internal structure with fewer voids or inclusions. This minimizes the risk of cracks or failures, even under high loads or extreme conditions. In comparison, cast parts are more prone to porosity and internal defects.

3. Excellent Corrosion and Temperature Resistance

Titanium naturally forms a protective oxide layer, making it highly resistant to corrosion in seawater, acids, and other aggressive environments. Forged titanium retains this property while also offering excellent performance at elevated temperatures — up to 400°C for Grade 5 alloys — making it suitable for both marine and aerospace engines.

4. Better Material Efficiency

Forging allows near-net-shape production, meaning less material is wasted compared to machining from solid bar or plate. It also reduces the need for extensive downstream processing, which lowers total production cost and shortens lead time.

5. Longer Service Life & Lifecycle Value

Because of their strength, durability, and resistance to wear, forged titanium parts often outlast other metal components, even in harsh environments. This reduces replacement frequency and total lifecycle cost — a key benefit for industries focused on performance and reliability.

In short, titanium forging combines precision, performance, and long-term value — making it a smart choice for applications where failure is not an option.

Titanium Forging vs Titanium Casting – A Practical Comparison

When sourcing titanium parts, the manufacturing method directly impacts strength, durability, cost, and design flexibility. Forging and casting are both viable techniques, but each comes with trade-offs. Below is a clear comparison to help you make an informed decision based on performance and application needs.

Titanium Forging

Process:

Titanium is heated (but not melted) and deformed under high pressure using presses or hammers. The grain structure is aligned with the shape of the part, improving overall strength and fatigue resistance.

Key Advantages:

-

Superior mechanical strength and fatigue performance

-

Dense, defect-free internal structure

-

Well-suited for high-load, safety-critical applications

-

Efficient material usage with near-net-shape options

Best for:

Aerospace components, medical implants, marine hardware, energy systems — any application where structural integrity and long-term reliability are essential.

Titanium Casting

Process:

Titanium is melted and poured into a mold to form complex shapes. Once solidified, the casting is removed, cleaned, and usually machined to final dimensions.

Key Advantages:

-

Capable of producing complex geometries

-

Lower tooling costs for small production runs

-

Suitable for non-structural or decorative parts

Limitations:

-

Higher risk of internal defects (porosity, shrinkage)

-

Lower mechanical strength compared to forgings

-

Requires more post-processing and finishing steps

Best for:

Intricate or artistic shapes, non-critical components, or cost-sensitive applications where strength is not the top priority.

Typical Applications of Forged Titanium Components

Forged titanium is trusted across industries where performance, reliability, and weight reduction are non-negotiable. Thanks to its excellent strength-to-weight ratio, fatigue resistance, and corrosion protection, it is used in some of the most demanding environments on earth — and beyond.

Here’s how different industries take advantage of forged titanium parts:

Aerospace & Aviation

The aerospace sector is one of the largest consumers of forged titanium. The material’s high strength and low weight directly contribute to fuel efficiency, payload capacity, and long-term structural reliability.

Common forged components include:

-

Engine discs and compressor blades

-

Landing gear parts and actuators

-

Structural brackets and fasteners

-

Exhaust and heat shielding systems

Titanium's resistance to fatigue and elevated temperatures makes it ideal for both airframes and jet engines, especially in commercial aviation, defense aircraft, and spacecraft.

Medical & Healthcare

Titanium’s excellent biocompatibility and corrosion resistance make it the material of choice for surgical tools and long-term implants.

Forged medical-grade titanium is used in:

-

Hip and knee joint implants

-

Bone screws, plates, and spinal devices

-

Dental implants and abutments

-

Surgical instruments that require sterilization

Forging improves the fatigue strength and structural purity of these parts, ensuring long-term safety and performance inside the human body.

Marine & Offshore Engineering

In seawater and aggressive marine environments, forged titanium resists corrosion far better than stainless steel or other alloys — even under high pressure and stress.

Typical applications include:

-

Propeller shafts

-

Seawater valves and fittings

-

ROV and submersible housings

-

Heat exchangers and condenser parts

The combination of lightweight, strength, and corrosion resistance makes titanium forgings an asset for ships, offshore platforms, and subsea systems.

Automotive & Motorsports

In high-performance and electric vehicles, forged titanium parts help reduce weight while maintaining mechanical strength — improving acceleration, fuel efficiency, and handling.

Examples include:

-

Suspension components

-

Connecting rods

-

Valves and valve springs

-

Exhaust system components

Although less common in mass production due to cost, forged titanium is widely used in racing, aerospace-derived cars, and next-gen vehicle platforms.

Industrial, Energy & Defense

Titanium forgings also support mission-critical equipment in chemical plants, power generation, and defense systems.

Applications include:

-

Pressure vessel components

-

Chemical processing flanges

-

Missile structures and armor

-

Nuclear reactor hardware

Where safety and long-term durability are vital, titanium forging offers unmatched performance.

Conclusion – Reliable Titanium Forging Solutions

Titanium forging is the perfect choice for high-performance applications that require strength and durability. AEM Metal provides a wide range of forged titanium parts, including rings, discs, flanges, and shafts, all made to meet your exact specifications. Whether you're working in aerospace, medical, marine, or industrial sectors, we ensure our parts meet the highest quality standards and are delivered on time.

When you choose AEM Metal, you get expert advice on selecting the right titanium grade for your project, flexible ordering options, and a full range of services, including machining, heat treatment, and finishing. We also handle all shipping and export requirements, making it easy for you to receive your order anywhere in the world.

If you're ready to get started or need more information, contact AEM Metal today. We're here to provide the titanium forging solutions that will help your project succeed.