ASTM F136 Titanium Overview: Properties, Standards, and Applications

views, Updated: February 10, 2026 by aemmetal

Introduction

ASTM F136 titanium is one of the most widely used

medical-grade titanium materials in the world. It is best known as

Ti-6Al-4V ELI, a titanium alloy specifically developed for applications where

strength, biocompatibility, and reliability are critical. Because it meets strict chemical and mechanical requirements, ASTM F136 titanium is commonly specified for medical implants and surgical devices.

Compared with standard titanium alloys, ASTM F136 has

lower levels of oxygen and other interstitial elements, which helps improve toughness and fatigue resistance. This makes it especially suitable for long-term use inside the human body, where material performance and safety cannot be compromised.

At

AEM Metal, we supply ASTM F136 titanium materials for medical and precision engineering applications. This article explains what ASTM F136 titanium is, its key properties, typical uses, and what to consider when sourcing this medical-grade material.

What Is ASTM F136 Titanium?

ASTM F136 titanium is a

medical-grade titanium alloy standard defined by ASTM for surgical implant applications. In practical terms, it refers to

Ti-6Al-4V ELI, where

ELI stands for

Extra-Low Interstitial. This means the material contains very low levels of oxygen, nitrogen, carbon, and iron.

The ASTM F136 standard sets

strict requirements for chemical composition, mechanical properties, and material quality. These controls ensure the titanium is safe, consistent, and reliable for use inside the human body. Because of this, ASTM F136 titanium is commonly required by medical device manufacturers for critical implant components.

Compared with standard Ti-6Al-4V alloys, ASTM F136 offers:

-

Better toughness

-

Improved fatigue performance

-

Extra-low interstitial elements (O, N, C)

-

Reduced metal ion release

-

Higher consistency for long-term medical use

Due to these advantages, ASTM F136 titanium is widely used in orthopedic implants, dental implants, and other load-bearing medical devices where failure is not an option.

Chemical Composition and Material Requirements

ASTM F136 titanium is a

Ti-6Al-4V ELI (Extra-Low Interstitial) alloy developed specifically for surgical implant applications. Its chemical composition is tightly controlled to ensure

biocompatibility, mechanical stability, and long-term reliability inside the human body.

The alloy mainly contains:

-

Aluminum (Al): 5.5%–6.5%Increases strength while keeping the material lightweight.

-

Vanadium (V): 3.5%–4.5%Improves toughness and fatigue resistance under repeated loading.

What sets ASTM F136 apart is the strict limitation of interstitial and impurity elements. These elements are carefully restricted because even small amounts can negatively affect implant performance.

Key impurity limits include:

-

Oxygen (O): ≤ 0.13%

-

Nitrogen (N): ≤ 0.05%

-

Carbon (C): ≤ 0.08%

-

Hydrogen (H): ≤ 0.012%

-

Iron (Fe): ≤ 0.25%

By minimizing these elements, ASTM F136 titanium achieves better ductility, improved fatigue life, and reduced risk of metal ion release. This level of chemical control is essential for materials used in long-term implants, where safety, consistency, and durability are critical.

Typical Applications of ASTM F136 Titanium

ASTM F136 titanium is mainly used in

medical and surgical applications where high strength, safety, and long-term reliability are required. Because it is a medical-grade Ti-6Al-4V ELI alloy, it is especially suitable for implants that remain inside the human body for many years.

Orthopedic implants

ASTM F136 titanium is widely used for hip and knee joint replacements, bone plates, screws, and trauma fixation devices. Its high strength and good fatigue resistance allow these implants to handle body weight and repeated movement without failure.

Dental implants and components

In dentistry, ASTM F136 titanium is commonly used for dental implants, abutments, and implant screws. Its excellent corrosion resistance and compatibility with bone help ensure stable osseointegration and long service life.

Spinal implants

Spinal rods, pedicle screws, and fixation systems often use ASTM F136 titanium. The material provides the strength needed to support the spine while remaining lightweight, which helps improve patient comfort.

Surgical instruments

Some high-quality surgical instruments are made from ASTM F136 titanium due to its strength, corrosion resistance, and ability to withstand repeated sterilization.

Other high-performance uses

Although ASTM F136 is primarily a medical standard, its strength-to-weight ratio and corrosion resistance also make it suitable for select aerospace and precision engineering applications where material reliability is critical.

These applications show why ASTM F136 titanium is a preferred material for

critical, long-term medical devices that demand consistent performance and strict standards compliance.

ASTM F136 Titanium Supply Capabilities at AEM Metal

At

AEM Metal, we supply ASTM F136 titanium materials that meet the strict requirements of medical and precision engineering applications. Our focus is on

material consistency, reliable documentation, and flexible supply, supporting both standard and custom project needs.

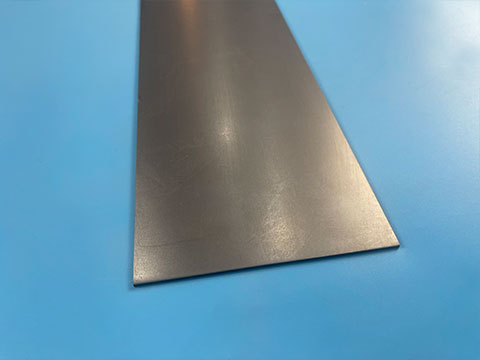

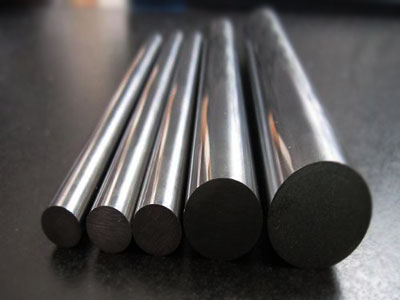

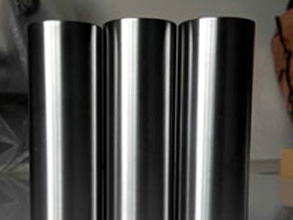

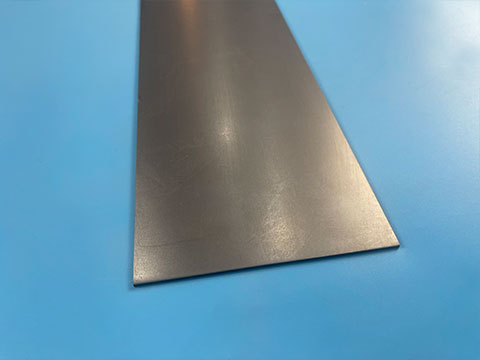

Available product forms

We offer ASTM F136 titanium in a wide range of wrought forms, including bars, rods, plates, sheets, wires, and tubes. Custom dimensions and tolerances can be provided based on drawing or application requirements.

Customization and small-batch support

AEM Metal supports OEM and R&D projects that require non-standard sizes, special surface conditions, or small order quantities. This flexibility is especially important for medical device development and pilot production.

Quality and traceability

All ASTM F136 titanium materials are supplied with complete traceability and mill test certificates. Chemical composition, mechanical properties, and inspection results are clearly documented to support regulatory and quality audits.

Export and project experience

With experience supplying international customers, AEM Metal understands the documentation and packaging requirements for global medical markets. Our stable supply chain helps ensure consistent lead times and dependable material quality.

By combining technical understanding with responsive service, AEM Metal supports customers seeking

reliable ASTM F136 titanium solutions for critical applications.

ASTM F136 vs ASTM F67: Key Differences for Medical Implants

ASTM F136 and ASTM F67 are both widely used titanium standards in the medical field, but they are designed for

different performance requirements and application scenarios.

Material type

ASTM F136 specifies

Ti-6Al-4V ELI, a titanium alloy containing aluminum and vanadium. In contrast, ASTM F67 covers

commercially pure (CP) titanium, which contains no intentional alloying elements. This fundamental difference directly affects strength and mechanical performance.

Mechanical performance

ASTM F136 offers significantly higher strength and better fatigue resistance than ASTM F67. This makes ASTM F136 suitable for

load-bearing implants such as hip joints, bone screws, and spinal fixation systems. ASTM F67, while strong enough for many uses, is typically selected for

lower-stress applications.

Biocompatibility and corrosion resistance

Both standards provide excellent biocompatibility and corrosion resistance in physiologicalenvironments. ASTM F67 is sometimes preferred when maximum material purity is required, while ASTM F136 is chosen when higher mechanical strength is essential.

Typical applications

-

ASTM F136: orthopedic implants, dental implants, spinal devices

-

ASTM F67: dental components, bone plates, non-load-bearing implants

In summary, ASTM F67 focuses on purity and corrosion resistance, while ASTM F136 delivers a stronger, more fatigue-resistant solution. The choice depends on whether the application prioritizes

mechanical strength or material simplicity.

Ti-6Al-4V ELI vs Ti-6Al-7Nb: Comparing Two Medical-Grade Titanium Alloys

Ti-6Al-4V ELI and Ti-6Al-7Nb are both

medical-grade titanium alloys used for surgical implants. They are similar in many ways, but they differ mainly in

alloy elements and typical use cases.

Composition differenceTi-6Al-4V ELI contains aluminum and a small amount of vanadium. The “ELI” version has very low oxygen and impurity levels, which helps improve toughness and long-term reliability.Ti-6Al-7Nb replaces vanadium with

niobium, making it a vanadium-free alloy.

Biocompatibility

Both materials are safe for use inside the human body and resist corrosion in body fluids. Ti-6Al-7Nb is sometimes chosen for patients who may be sensitive to vanadium, while Ti-6Al-4V ELI has a long and proven history in medical implants.

Strength and durability

Ti-6Al-4V ELI is known for its high strength and good fatigue resistance, which makes it suitable for load-bearing implants such as joints and spinal devices. Ti-6Al-7Nb also offers good strength but is less commonly used in high-stress applications.

Availability and industry use

Ti-6Al-4V ELI is the most widely used medical titanium alloy and is easy to source globally. Ti-6Al-7Nb is used in specific applications but is less common and may have more limited availability.

In simple terms,

Ti-6Al-4V ELI is the standard choice for most medical implants, while

Ti-6Al-7Nb is an alternative when a vanadium-free material is required.

Conclusion

ASTM F136 titanium is one of the most trusted materials used in medical implants today. As a

Ti-6Al-4V ELI medical-grade alloy, it provides the strength, corrosion resistance, and biocompatibility needed for long-term use inside the human body. This is why it is commonly used in orthopedic, dental, and spinal applications.

Compared with other medical titanium grades, ASTM F136 offers a proven combination of performance and reliability. Its strict material requirements and long track record in clinical use help medical manufacturers reduce risk and ensure consistent product quality.

At

AEM Metal, we supply ASTM F136 titanium in various forms with full certification and traceability. If you are looking for a reliable ASTM F136 titanium supplier or need custom material support,

contact our team to discuss your project requirements.