Nickel Molybdenum Alloy: High-Performance for Tough Applications

views, Updated: December 31, 2025 by aemmetal

Introduction to Nickel Molybdenum Alloy

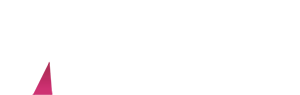

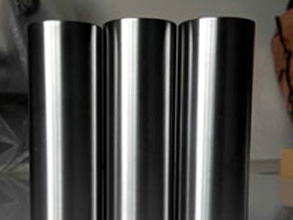

Nickel Molybdenum Alloy is a strong and durable metal made by combining nickel and molybdenum. This combination creates a material that can withstand high heat, corrosion, and stress, making it perfect for industries where performance under extreme conditions is essential.

Key Characteristics of Nickel Molybdenum Alloy

-

Nickel: Offers excellent resistance to corrosion and keeps the material strong, even in high temperatures.

-

Molybdenum: Improves the alloy’s ability to handle high temperatures and stress, while also boosting corrosion resistance.

This alloy is ideal for industries where equipment and parts are exposed to extreme heat, high pressure, or corrosive substances.

Why Choose Our Nickel Molybdenum Alloys?

At AEM Metal, we provide custom Nickel Molybdenum Alloys that meet your specific needs. Whether you need a solution for high-temperature equipment, corrosive environments, or stress-resistant parts, our alloys are built to last. We focus on delivering high-quality, durable products with fast delivery to ensure your projects run smoothly.

Properties of Nickel Molybdenum Alloy

Nickel Molybdenum Alloy is valued for its strength, durability, and ability to resist heat and corrosion. These qualities make it ideal for industries that need materials to perform in tough conditions. Let’s look at the main properties that make this alloy stand out.

Mechanical Properties

-

Strength and Durability: This alloy is very strong, even at high temperatures. It can handle heavy stress and high pressure, making it perfect for parts used in aerospace and energy industries.

-

Corrosion Resistance: The alloy also resists rust and damage from chemicals or saltwater, making it great for industries like chemical processing and marine applications. It stays in good condition even in harsh environments.

Thermal and Electrical Conductivity

-

High-Temperature Performance: Nickel Molybdenum Alloy can tolerate high heat without losing strength or structure. This makes it ideal for use in engines, turbines, and energy plants, where extreme heat is common.

-

Electrical Conductivity: While this alloy isn’t the best conductor of electricity, it still performs well in certain applications where both strength and resistance to heat are important, like in electrical parts exposed to high temperatures.

Workability and Fabrication

-

Easy to Shape and Machine: Nickel Molybdenum Alloy is easy to cut, weld, and shape, making it ideal for custom parts. It holds up well during fabrication, so you can create the exact parts you need for your project.

-

Weldability: This alloy can be welded into complex shapes and parts without losing its strength. This is why it's a great choice for industries that need custom solutions that require welding.

Applications of Nickel Molybdenum Alloy in Your Industry

Nickel Molybdenum Alloy is used in many industries because of its ability to perform in extreme conditions. Let’s look at some of the main industries and applications where this alloy shines.

Aerospace and Aviation

Nickel Molybdenum Alloy is commonly used in aerospace for components that need to handle high stress and extreme temperatures, like jet engines and turbine blades. Its ability to maintain strength and resist heat makes it perfect for aircraft parts that operate in tough environments.

-

Why It’s Important: This alloy helps make airplanes and spacecraft safer and more efficient by providing durable parts that last longer and perform better at high altitudes and temperatures.

Chemical Processing Industry

In the chemical industry, parts that deal with corrosive chemicals or high heat need to be made of materials that resist damage. Nickel Molybdenum Alloy is often used in reactors, heat exchangers, and pipes in chemical plants. It helps prevent corrosion and keeps equipment running smoothly.

-

Why It’s Important: It reduces the need for frequent repairs or replacements, which can be costly and time-consuming.

Marine and Offshore Applications

Nickel Molybdenum Alloy is highly resistant to saltwater corrosion, which makes it ideal for use in marine and offshore environments. It’s used in offshore drilling platforms, ship components, and submarine parts, where parts are exposed to seawater and harsh conditions.

-

Why It’s Important: It helps prevent rust and extends the life of marine equipment, even when exposed to the toughest conditions.

Energy Industry

In the energy sector, especially in nuclear power plants and oil & gas, parts must handle extreme temperatures and high pressures. Nickel Molybdenum Alloy is used in heat exchangers, turbines, and reactors because it can withstand these tough conditions without breaking down.

-

Why It’s Important: This alloy plays a key role in making sure that energy production equipment runs safely and efficiently, reducing downtime and improving performance.

The Benefits of Choosing Our Nickel Molybdenum Alloy

Choosing the right material is crucial for ensuring the success of your projects. Our Nickel Molybdenum Alloy offers several benefits that make it a top choice for industries demanding high-performance materials. Here’s why our alloy stands out:

Cost Efficiency

Our Nickel Molybdenum Alloy offers long-lasting durability, which means fewer replacements and less maintenance over time. By using our alloys, you can reduce long-term costs related to repairs and downtime.

-

How It Helps You: The alloy’s strength and resistance to corrosion and high temperatures mean your equipment lasts longer, cutting down on the need for costly repairs or replacements.

Performance and Reliability

Our Nickel Molybdenum Alloy is engineered to perform in extreme environments. Whether it’s high temperatures, pressure, or corrosive chemicals, our alloy ensures that your equipment keeps running smoothly without breaking down.

-

How It Helps You: By choosing our alloy, you can rely on consistent performance, even in the most demanding applications. This reliability helps you meet your project goals without unexpected failures.

Versatility Across Industries

We offer customized Nickel Molybdenum Alloys to meet the specific needs of various industries, from aerospace to chemical processing. Our alloys can be tailored to fit your unique requirements, ensuring that you get exactly what you need.

-

How It Helps You: With custom solutions, you get a material that’s perfectly suited for your application, ensuring the best possible performance and durability.

Conclusion

Nickel Molybdenum Alloy is an exceptional material known for its strength, durability, and resistance to extreme conditions. Whether your project involves aerospace, chemical processing, marine, or energy, this alloy provides the reliability and performance needed to succeed in the most demanding environments.

At

AEM Metal, we offer high-quality Nickel Molybdenum Alloys tailored to meet your specific needs. Our alloys are designed to perform consistently in high-stress, high-temperature, and corrosive environments. With our custom solutions, we ensure you get the perfect material for your project, backed by trusted expertise and precision manufacturing.

Ready to find the right Nickel Molybdenum Alloy for your needs?

Contact us today for a custom quote and expert guidance on selecting the best alloy for your project. With our high-performance materials, personalized service, and fast delivery, we are here to support your business every step of the way.