What is AMS 4902 Titanium?

AMS 4902 refers to a specification for Grade 2 titanium, also known as commercially pure titanium. This grade is made up of about 99% titanium, with small amounts of other elements like iron and oxygen, giving it its unique properties.

Grade 2 titanium is valued for its balance of strength, corrosion resistance, and lightweight nature. It’s an ideal material for industries where performance and durability are essential, especially in aerospace, medical, and industrial applications.

Whether it’s for aerospace parts, medical implants, or industrial components, this material’s combination of strength, durability, and versatility makes it a top choice for high-performance applications.

Key Benefits of Grade 2 Titanium

Grade 2 titanium offers outstanding performance for a wide range of demanding applications. With its strength, corrosion resistance, and ease of use, it’s a preferred choice for industries like aerospace, medical, and marine. Here are the key benefits:

Strength with Lightness

It offers excellent mechanical strength while maintaining a low density, making it ideal for applications where minimizing weight is important, without sacrificing performance.

Exceptional Corrosion Resistance

This grade of titanium is highly resistant to corrosion, especially in seawater and other harsh environments. This makes it ideal for marine applications, where parts are constantly exposed to corrosive elements. Its resistance helps ensure that components stay strong and functional for long periods, reducing the need for frequent maintenance or replacements.

Easy to Machine

Thanks to its excellent machinability, Grade 2 titanium is easier to process and shape compared to other titanium grades. This allows manufacturers to create parts with high precision and efficiency, making production more cost-effective and faster.

Stronger than Grade 1 Titanium

Grade 2 titanium is stronger than Grade 1 titanium, while maintaining the same excellent corrosion resistance. This makes it a great choice when higher strength is required without sacrificing durability, especially in applications where performance is critical.

Moderate Strength

While Grade 2 titanium doesn’t offer the high strength of alloys like Grade 5, it still provides moderate strength that is ideal for many applications. Its lightweight, strength, and corrosion resistance make it a reliable and versatile material for various industries.

Applications of Grade 2 Titanium

Grade 2 titanium is known for its strength, lightweight nature, and exceptional corrosion resistance, making it an excellent choice for a wide range of industries. Below are the key applications across various sectors:

Aerospace and Aviation

Grade 2 titanium is widely used in the aerospace industry for its strength-to-weight ratio and durability. Key applications include:

-

Airframe skins: Reducing weight while maintaining structural integrity.

-

Exhaust components: Resistant to high temperatures and corrosion, making it ideal for exhaust systems.

Chemical and Marine Industries

In chemical processing and marine environments, Grade 2 titanium is favored for its corrosion resistance. Common applications include:

-

Chemical process vessels: Handling aggressive chemicals without degrading.

-

Heat exchangers: Ensuring longevity in corrosive conditions.

-

Marine hardware: Resisting saltwater corrosion in harsh marine environments.

Medical and Dental Applications

Grade 2 titanium is highly valued in the medical field for its biocompatibility and strength. It is commonly used in:

-

Medical implants: Bone plates, joint replacements, and other implants that require strength and durability.

-

Dental implants: Providing safe, long-lasting solutions for tooth replacement.

Energy and Power Generation

Grade 2 titanium's thermal stability and corrosion resistance make it essential in energy systems. Applications include:

-

Heat exchangers: Used in power plants for effective heat transfer and durability.

-

Cooling systems: Essential for maintaining temperature control in high-performance environments.

Additional Industrial Uses

Grade 2 titanium’s versatility extends to a variety of industrial applications:

-

Sputtering targets: Used in semiconductor and electronics manufacturing.

-

Exhaust systems: In automotive and other high-heat applications.

-

Heating coils: Withstanding high temperatures and corrosive environments.

-

Conduits: For transporting fluids and gases in demanding conditions.

Custom Grade 2 Titanium Products Tailored to Your Needs

At AEM Metal, we offer a wide range of Grade 2 titanium products, customized to meet the unique requirements of your projects. Our extensive inventory and ability to produce custom solutions ensure that you’ll find the perfect materials for your needs, whether for aerospace, medical, industrial, or marine applications. Each product is made using the best manufacturing method to ensure top performance and quality.

Available Products:

-

Titanium Sheets: Our Grade 2 titanium sheets are strong and durable, making them ideal for critical applications such as aerospace parts, marine hardware, and chemical processing equipment. These sheets are typically made by rolling, then CNC machined to ensure precise size and smooth surfaces.

-

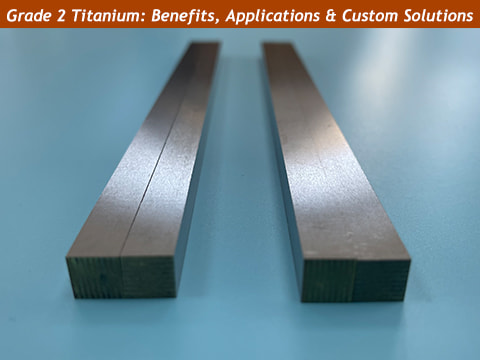

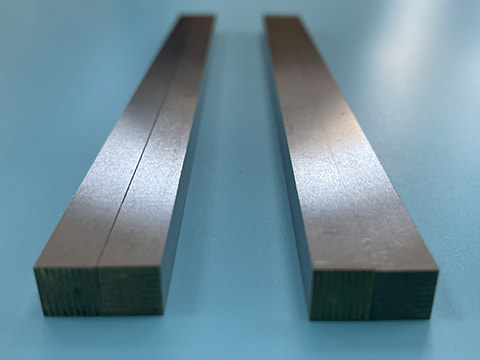

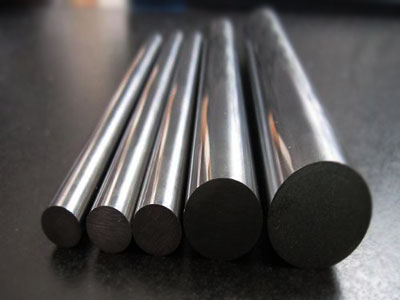

Titanium Bars: We offer Grade 2 titanium bars in various sizes, perfect for making parts like fasteners, valves, and structural components. These products are usually made by forging or extrusion, and then refined using CNC machining for exact dimensions and smooth finishes.

-

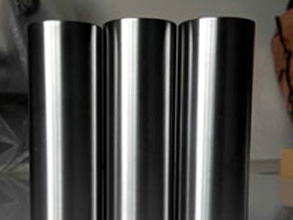

Titanium Tubes: Our Grade 2 titanium tubes are designed for demanding applications such as heat exchangers, exhaust systems, and pipes. They are produced by extrusion, then treated with heat to enhance their strength. Afterward, CNC processing ensures they meet the precise size and length requirements. These tubes perform reliably under tough conditions.

Custom Solutions

We understand that every project has unique needs, so we offer custom machining and fabrication services. Whether you need specific sizes, shapes, or finishes, we work with you to create the perfect solution that meets your exact requirements.

Conclusion: Grade 2 Titanium – A Reliable Choice for Performance and Durability

Grade 2 titanium is the perfect combination of strength, lightweight, and corrosion resistance, making it an excellent material for industries that demand long-lasting reliability and high performance. Whether you're working in aerospace, medical, marine, or chemical processing, Grade 2 titanium offers the durability you need in challenging environments.

From aircraft components to medical implants, this titanium grade ensures that your products maintain their integrity and performance over time. Its biocompatibility, ease of fabrication, and strength-to-weight ratio make it a top choice for a wide range of applications.

At AEM Metal, we offer a full range of Grade 2 titanium products, including tubes, bars, sheets, and custom solutions. Whether you're working on an aerospace project, creating medical devices, or need durable industrial components, we provide high-quality titanium products that meet your exact needs.

Contact us today to learn more about how our Grade 2 titanium solutions can help with your next project. Let us provide you with the right material and support for your business.